Welder tech has come a long way, and industrial laser welder systems are now the gold standard for many manufacturers. They blend pinpoint accuracy, speed, and dependability into one impressive tool. Innovations like AI-driven adjustments and real-time monitoring mean these machines basically self-optimize mid-weld—less fiddling, fewer mistakes, and more consistent results.

Advanced Laser Sources & Beam Control

The magic really happens in the beam itself. A modern industrial laser welder comes with top-of-the-line laser sources and beam tech that give you an edge in both precision and speed.

High‑Power Fiber & Disk Lasers

Fiber and disk lasers are the workhorses here. Fiber lasers give you a clean, focused beam that handles metals like stainless and aluminum like a champ. Disk lasers crank out high power with minimal distortion—ideal for bigger jobs without overheating your parts.

Ultrafast & Multimode Lasers

These are the tools you reach for when you need real finesse. Ultrafast lasers fire off pulses so quickly that heat barely has time to spread—perfect for delicate metal or intricate patterns. Denaliweld offers systems that harness this precision for high-detail work. Multimode lasers, on the other hand, let you switch things up based on your material—thin sheet or thick steel, they’ve got you covered.

Beam Shaping & Adaptive Optics

Imagine sculpting light to suit your weld. Beam shaping and adaptive optics let you tweak the laser’s profile for exactly the result you need—think sharper welds, stronger joints, less trial and error. Adaptive optics even adjust mid-weld to keep things just right.

Source: https://denaliweld.com/fiber-laser-welding-everything-you-need-to-know/

Hybrid Welding & Process Integration

Why choose one method when you can combine them? Hybrid welding gives you the best of multiple techniques.

Laser‑Hybrid Welding

Pairing a laser with arc welding brings serious benefits: deeper penetration, faster throughput, and stronger joints. Perfect when a precise yet robust weld is what the job demands.

Laser-Guided Arc Welding

Here, lasers guide arc welding to hit the sweet spot every time. Sensors track your weld and auto-adjust to keep things clean and steady—great for tricky jobs or uneven materials.

Combined Cutting–Welding Systems

Got both cutting and welding on your to-do list? Combine them in one system and save a ton of time and retooling headaches. Just set it and go.

Automation, AI & Real-Time Monitoring

We’re well into the era of “smart factories,” and industrial laser welders are leading the charge.

AI‑Driven Parameter Control

These systems don’t just weld—they learn. They analyze past jobs and tweak settings on the fly based on what they sense in real time. That means cleaner welds with less babysitting required.

Sensor-Based Monitoring

Temperature, beam intensity, alignment—everything gets watched. And if something starts to drift off, the machine corrects itself immediately, keeping your welds spot-on.

Industry 4.0 & Connected Systems

These welders aren’t islands—they’re connected. They can talk to other machines, schedule maintenance, and even reorder parts automatically. All together, it’s a leap toward zero-downtime production.

Safety & Operator Ergonomics

Powerful tools should also be safe and user-friendly, and these welders deliver.

Enclosed Welding Cells

These are basically safety bubbles: contained, ventilated, and shielded. If a door opens mid-weld, it shuts down immediately—no sparks or stray beams getting out.

Smart Interlocks & Shields

Motion sensors, safety shields, automatic shutoffs—you name it. Operators are protected in real time, and the system automatically pauses if anything seems off.

Ergonomic System Designs

Long shifts are way easier with ergonomic controls and adjustable stations. Lighted shields, touchscreen interfaces—you get a system that’s built for humans, not just machines.

New Application Domains

Laser welders aren’t just for factories anymore. They’re branching into exciting new fields.

Additive Manufacturing (Metal AM)

Laser welding is helping build complex metal parts layer by layer. That means tighter tolerances, fewer imperfections, and faster post-processing—brilliant for prototype or custom part production.

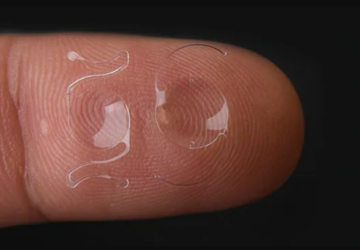

Dissimilar & Transparent Material Welding

Joining metal to glass—or steel to plastics? Totally doable now. Lasers let you fuse different materials without adhesives or mechanical fasteners, creating cleaner, stronger joins for everything from medical devices to consumer electronics.

Renewable Energy & EV Industries

Laser welds are now standard in battery housings and solar panel assemblies. In EVs, precision welding can help shave ounces off each vehicle, boosting range and efficiency.

Sustainability & Efficiency Gains

Today, sustainability isn’t optional—it’s essential. And laser welders are doing their part.

Reduced Heat Input & Waste

Laser welds focus heat where it matters, cutting down on scrap and distortion. That’s less grinding, less rework, and less waste heading to the landfill.

Energy-Efficient Lasers

Modern fiber and disk lasers sip power but deliver punch. Faster welding, less downtime—add it up, and you’re looking at a tool that pays for itself not just in performance, but in reduced energy bills, too.

Conclusion

Industrial laser welders are doing more than just welding—they’re transforming manufacturing from the inside out. With smart features, ultrahigh precision, and unmatched speed, they’re helping businesses do better work faster and cleaner. It’s not just a tool upgrade—it’s a game-changer for anyone serious about building efficiently and sustainably.

Thinking it might be time to invest? An industrial laser welder isn’t just a purchase—it’s a step into the future.