In the modern age, as summer heat intensifies, home air conditioning is more important than ever. Consequently, it is advisable to address AC cooling issues as soon as possible. This prevents the minor issues from escalating into larger air conditioning problems that are more complicated and costly to repair.

However, to avoid air conditioning issues, keep your AC maintenance up to date. Familiarizing yourself with various air conditioning mechanisms is critical so that minor problems do not cause discomfort and trouble for everyone at home.

The AC Contactor is one of the air conditioning devices that homeowners must be aware of, should it wear out and disrupt the operation of the central AC.

What’s An AC Contactor?

To begin with, a contactor is an electrically controlled switch that connects and disconnects power to big lighting loads and motors. Besides, contactors are composed of basic components: several normally-open power contacts and a coil, or an electromagnet. When current flows through the coil, a moving contact attracts and hangs onto a fixed contact. On the other hand, while the coil is de-energized, the contacts open and power to the load is turned off.

Contactors correctly matched and suited to their application can provide years of uninterrupted service. If there’s a premature AC contactor failure, there is usually a clear cause. To avoid repeated failure, however, always examine the contactor to identify why it failed before replacing it with another identical unit.

There are several common reasons why contractors fail, some of which are discussed in the rundown.

What Causes Faulty Contacts?

1. Stuck in Closed Position

This can occur if the contacts are fused as a result of high amperage melting them together.

This can be tested with a multimeter.

Attach the multimeter probes, one on each side of the contacts, after turning off the power and disconnecting the wires from the contactor coil and contacts. In the preceding case, the contact resistance is 2 Ohms. This indicates that it is in a closed position.

Since there is no electricity to the coil, the contactor should not be closed. You’ll have to eventually replace the contactor. In addition, measure the amp draw on the compressor to see if there is another issue and to ensure that the device is running correctly.

2. A High Electrical Resistance

This could be caused by pitting on the actual contacts. This is induced by arcing and partial melting on the contact face. This melting causes the contacts to not properly touch when they should be closed.

If you administer an average contactor, it’s usually powered by 24 volts. The reading would be 3.2 megaOhms. This shows that, while the switch is closed, the contacts are not in touch. This produces extraordinarily high resistance to reading.

If this is being experienced, consider replacing the contactor. In addition, measure the amp draw on the compressor to see if there is another issue and to ensure that the device is running properly.

3. Ants, Insects, & Cobwebs Within

Certain ants, such as the Red Tawny Ant, are drawn to the voltage at the contactor. As a result, they could become caught between contacts. Similarly, a spider or a spider web could be present between the contacts. As a result, the switch cannot close because the contacts do not touch.

So, look for cobwebs and other imprisoned insects while scanning the unit. This can prevent contacts from getting in touch. Besides, it is a common occurrence; thus, it is essential to be aware of the issue.

On the flip side, newer contactors are insulated, providing less access to the contactor and coil.

4. Burns Out Owing To Water/Excessive Amperage

If water is present at the contactor coil when turned on, it will eventually short out.

Make sure that the coil’s power is turned off, the cables are removed, and the electrical resistance is measured in ohms. If the multimeter reads OL, it stands for “open line” and indicates that the coil has burned out. When measuring electrical resistance, the coil is typically intact. Compare the electrical resistance reading to a known resistance on a new contactor with the same ratings to determine whether the electrical resistance is excessively high.

5. A Loose Electrical Connection | Incorrect Voltage

A corroded electrical connection at the spade terminal could cause the contactor coil to have low voltage and not close the contacts. Low voltage, in essence, could also result in a burned-out coil.

The wire from the indoor unit may have a poor connection, resulting in low voltage at the contactor. Make sure you measure the voltage applied to the coil. This should be between 24 and 29.5 volts

How Do You Test A Contactor?

To determine the state of an AC contactor, test it.

A multi-meter is a tool that can be found at most home improvement, hardware, or electronics stores.

- The first step is to turn off the power to the air conditioner, both through the thermostat or switch and at the breaker panel. This is to prevent electric shocks.

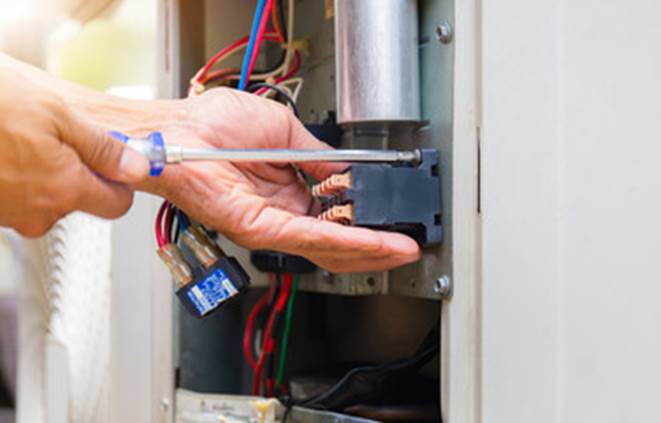

- The next step is to remove the condenser or outdoor unit’s side cover. The black rectangular device with colored wires connecting is the AC contactor.

- Set the multimeter to OL mode and connect the voltage terminals on both sides. If there is no problem with the AC contactor, the reading should be between 5 and 20. If the reading is less than five or none at all, the contactor has already worn out. Purchase a replacement part and install it using the image from before as a guide.

- Re-screw the condenser cover, switch on power from both the breaker and the AC unit and see if everything works. Alternatively, keep in mind that a .

Final Thoughts

Understanding how AC components operate and what causes them to wear down is essential for taking better care of your unit. It’s also beneficial to master basic troubleshooting techniques. However, if the problem persists after you have attempted to resolve it, it is necessary to seek professional assistance.