Most warehouses today still rely on AS400 systems for one simple reason: they work. They are reliable, stable, and have quietly kept inventory and logistics moving for decades.

But the way warehouses operate has changed. Orders move in real time, not overnight. Managers expect live dashboards, barcode scans that update instantly, and mobile access to data. Yet many teams still use systems with green text screens and reports that take hours to generate.

So the big question is this: Can an AS400-based Warehouse Management System really keep up with today’s real-time operations without being replaced?

Yes, it can.

You do not need to throw away what works. You just need to help it evolve. And that’s exactly what AS400 modernization is all about…keeping what’s reliable, upgrading what’s limited, and turning your existing system into a smarter, faster, and more connected warehouse platform.

What that Evolution Actually Looks Like

Most teams that modernize their AS400 don’t do it all at once. They start small, moving what already works to a better environment, connecting it with newer tools, and improving visibility step by step. That’s where the real transformation begins.

From Legacy to Agility

Modernizing AS400 does not mean rebuilding everything from scratch. It means moving what already works onto a stronger, more flexible foundation.

Many companies start by shifting their AS400 workloads to cloud or modern servers. This single step improves performance, lowers maintenance costs, and creates room for future upgrades.

You do not need to rewrite the entire system. Think of it as giving your warehouse engine a tune-up rather than buying a new truck. You get better speed, reliability, and scalability without interrupting daily work.

Making AS400 Work in Real Time

If your warehouse still depends on nightly updates for stock, shipping, or order data, you already know the frustration. By the time you see the report, things have changed.

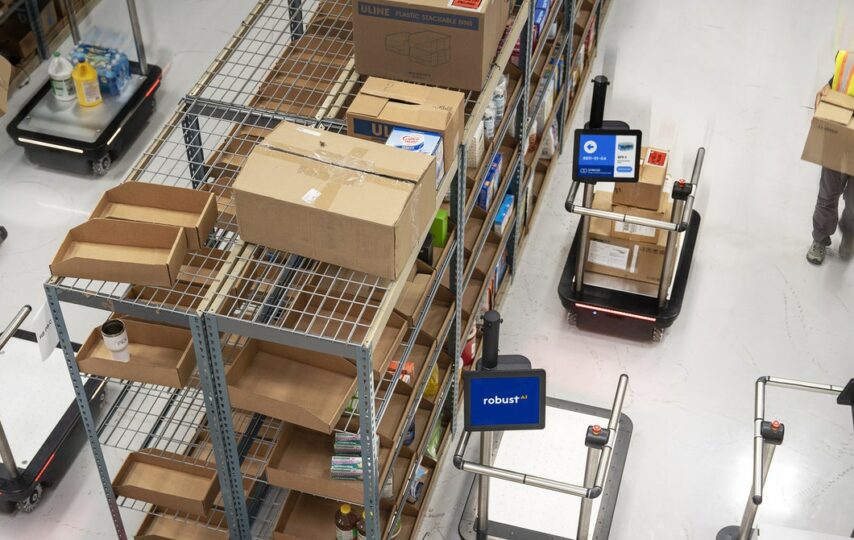

Adding APIs and event-based connections lets AS400 handle real-time tracking. Barcode scans, RFID readings, and IoT sensor data can feed directly into the system, keeping your numbers current throughout the day.

This means faster visibility, quicker problem solving, and fewer data mismatches. You are not replacing the AS400. You are connecting it to newer systems that speak real-time data.

Moving from Batch Jobs to Instant Insights

There was a time when warehouses could wait until night to process updates. Today, that model slows everything down. Modern supply chains need instant updates whenever products move.

You can make that happen by shifting from batch jobs to real-time event processing. For example, when a shipment leaves your facility, the system updates inventory right away instead of waiting for a nightly refresh.

This simple change speeds up fulfillment, improves coordination, and helps connected systems stay accurate. The AS400 becomes part of a living, connected network instead of a closed-off system.

Bringing the Interface into This Decade

Let’s be honest. The old green-screen interface still works, but it is not exactly user-friendly. For many employees, that’s the biggest barrier.

That’s where AS400 GUI modernization comes in. You can upgrade the interface without changing the system’s core logic. By replacing those terminal screens with clean web dashboards or mobile-friendly layouts, you make the system intuitive and far easier to use.

Managers can check live metrics on tablets, floor staff can track picks on handheld devices, and new hires can learn the workflow in minutes instead of days. The core technology of AS400 stays as reliable as ever, but with GUI modernization, it finally looks and feels like the modern system it has always been under the hood.

Finding the Real Value Hidden in AS400 Data

One of the biggest untapped opportunities inside AS400 systems is the data itself. Every transaction, shipment, and adjustment tells a story, but most of it never gets analyzed.

A study in the International Journal of Applied Information Systems found that companies using warehouse analytics tools saw up to 18 percent improvement in efficiency and space utilization. They achieved this by using their existing data to forecast demand, plan labor, and find bottlenecks.

You can do the same by connecting AS400 data to analytics tools such as Power BI or Tableau. Once you do, you can see patterns that were hidden before. You can predict reorder cycles, manage space better, and balance staffing during busy periods.

It is not just about looking back. It is about using your data to see what comes next.

A Practical Way to Modernize

If you are wondering where to start, here is a simple plan that works for most teams:

- Understand what works and what does not.

Map out your workflows and find where delays or data gaps occur. - Pick one starting point.

You can move the system to the cloud, replace nightly jobs with real-time updates, modernize the user interface, or start with analytics. - Go step by step.

Focus on quick wins that show results fast, like live dashboards or faster inventory updates. Build from there. - Measure results.

Track improvements in accuracy, speed, and cost savings. Real data helps guide the next phase of modernization.

Wrapping It Up

Your AS400 Warehouse Management System is not outdated. It is simply waiting for an upgrade that matches today’s pace of business. With a few smart changes, it can deliver real-time visibility, cloud scalability, and data insights without losing the reliability that made it valuable in the first place.

Cloud migration makes it scalable. APIs make it real time. A new interface makes it easy to use. Analytics makes it powerful.

You do not need a new system. You just need a smarter one.

If you’re ready to explore how to modernize your AS400 warehouse system, find a reliable AS400 support service provider who understands both legacy systems and modern warehouse needs. The right partner can help you plan each step, upgrade with confidence, and move your AS400 from reliable to inte lligent.