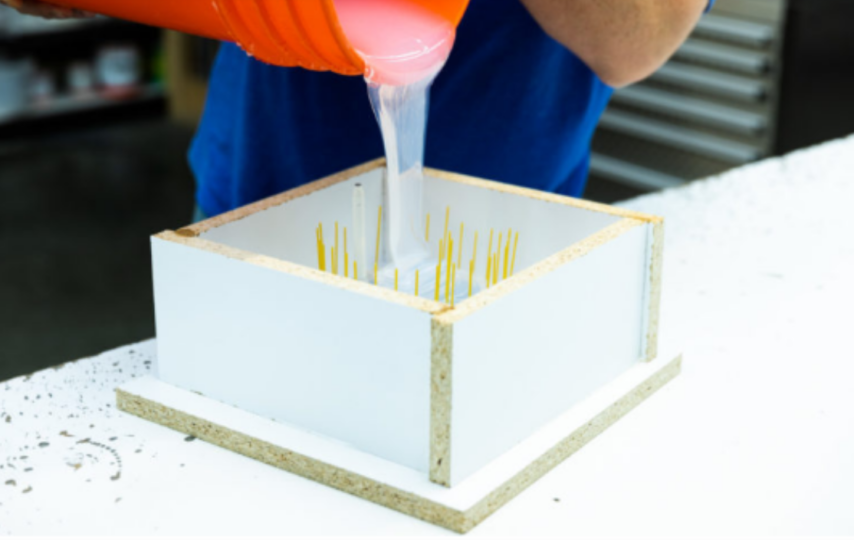

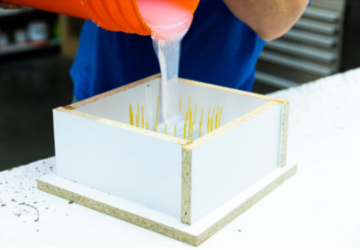

What Sets the Best Cast Urethane Casting Services Apart

The best cast urethane casting services distinguish themselves through a balance of technical precision, material expertise, and customer collaboration. These providers offer more than basic mold-making—they guide projects from early design validation through low-volume production with consistency and reliability. Key differentiators include high-quality master pattern creation, well-engineered silicone tooling, and controlled casting environments that reduce defects and improve repeatability. Experienced providers also emphasize communication, offering clear timelines, DFM feedback, and realistic expectations around mold life and tolerances. Certification standards such as ISO compliance further signal quality assurance and process control. Another defining factor is flexibility: the ability to adapt materials, finishes, and tooling strategies as designs evolve. By combining engineering insight with hands-on craftsmanship, the best cast urethane casting services help teams achieve production-ready parts without the cost or complexity of hard tooling.

How the Best Cast Urethane Casting Services Support Rapid Prototyping

Rapid prototyping is one of the strongest advantages offered by the best cast urethane casting services. These providers streamline the transition from CAD to physical parts by leveraging high-resolution master patterns, often produced with SLA or CNC machining. Silicone molds can be created quickly, allowing teams to validate form, fit, and function in days rather than weeks. This speed enables faster iteration, helping engineers test design changes without restarting the entire process. Urethane materials closely mimic production plastics, making prototypes suitable for functional testing and stakeholder review. In addition, service providers often offer finishing options such as painting, texture matching, or insert installation to deliver presentation-ready parts. By removing long tooling lead times, urethane casting allows product teams to move quickly, reduce development risk, and make informed decisions before committing to higher-volume manufacturing.

Low-Volume Production Benefits of the Best Cast Urethane Casting Services

Low-volume production is where the best cast urethane casting services provide exceptional value. Silicone tooling offers a cost-effective alternative to metal molds, making it ideal for short runs, bridge builds, and limited releases. These services allow manufacturers to produce dozens or hundreds of parts with consistent quality while avoiding large upfront tooling investments. This approach is particularly useful when demand forecasts are uncertain or when products are still evolving. Urethane casting supports repeatability across batches, ensuring that cosmetic and functional standards are maintained. Providers can also refresh molds or adjust designs between runs, offering flexibility that traditional tooling cannot. For companies launching new products, supporting early customers, or filling supply gaps, low-volume urethane casting delivers production-like parts with faster turnaround and lower financial risk.

Materials and Finishes Offered by the Best Cast Urethane Casting Services

Material versatility is a defining strength of the best cast urethane casting services. Providers offer a wide range of rigid and elastomeric urethanes that replicate properties of ABS, polypropylene, polyethylene, nylon, and polycarbonate. This allows teams to select materials based on strength, flexibility, temperature resistance, or visual appearance. Clear and tinted resins, along with varying durometers, support applications ranging from housings to seals and grips. Finishing options further enhance realism and performance. These may include matte or high-gloss surfaces, color matching, painting, polishing, and light post-machining. Some services also support overmolding-style builds or insert integration. This combination of material choice and finishing capability ensures that cast parts not only perform well but also closely resemble final production components in look and feel.

Industries Served by the Best Cast Urethane Casting Services in the US

The best cast urethane casting services support a wide range of industries that require speed, precision, and flexibility. In automotive and aerospace sectors, urethane casting is used for functional testing, interior components, and low-volume assemblies. Medical device companies rely on these services to produce housings, enclosures, and ergonomic components for validation and regulatory review. Consumer product manufacturers use urethane casting for early market testing and presentation-quality samples. Industrial and electronics sectors benefit from durable parts such as covers, brackets, and custom enclosures. Across these industries, the ability to replicate production materials without committing to mass manufacturing is critical. By serving diverse applications, urethane casting providers demonstrate adaptability and technical depth, helping teams across markets bring products to life faster and with greater confidence.

How to Choose the Best Cast Urethane Casting Services for Your Project

Choosing the best cast urethane casting services requires evaluating both technical capabilities and collaboration style. Start by reviewing a provider’s experience with similar part sizes, geometries, and industries. Ask about master pattern options, mold life expectations, and casting methods used for clear versus opaque parts. Transparency around timelines, tolerances, and revision handling is essential. Strong providers offer proactive DFM input, helping optimize wall thickness, parting lines, and material selection before tooling begins. Quality systems and certifications provide added assurance, especially for regulated industries. It’s also important to consider scalability—whether the service can support repeat orders or transition into other manufacturing methods if needed. Ultimately, the right partner combines engineering insight, process reliability, and responsive communication to support your project from prototype to production.

Conclusion

The best cast urethane casting services play a vital role in modern product development by bridging the gap between prototyping and full-scale production. Through flexible tooling, production-like materials, and fast turnaround times, these services enable teams to validate designs, meet early demand, and reduce manufacturing risk. Their value extends beyond part production, offering engineering guidance, material expertise, and finishing capabilities that support real-world performance and appearance. Whether used for rapid prototyping, low-volume runs, or bridge manufacturing, urethane casting delivers speed and adaptability without sacrificing quality. As product lifecycles shorten and customization increases, choosing the right urethane casting partner becomes increasingly important. By working with experienced providers that prioritize precision, communication, and scalability, manufacturers can bring better products to market faster and with greater confidence.