Photo by Pixabay: https://www.pexels.com/photo/electrician-fixing-an-opened-switchboard-257736/

Reliable electricity delivery forms the backbone of modern business operations, yet many organizations overlook critical vulnerabilities in their power infrastructure until disruptions occur. The financial impact of unexpected outages extends beyond immediate lost productivity, damaged equipment, compromised data systems, and safety hazards create cascading consequences that can threaten an organization’s viability. Understanding how to systematically address these risks requires examining proven strategies that protect both operational continuity and workplace safety across diverse business environments.

Understanding Why Reliable Electricity Delivery Matters for Business Continuity

When electrical systems fail, businesses face immediate operational disruptions that cascade through every department and function. Manufacturing lines halt, data centers go dark, and communication systems collapse, resulting in revenue loss and missed deadlines. Critical equipment may suffer damage from power surges or sudden shutdowns, requiring costly repairs and replacement.

Beyond immediate financial impact, power outages compromise employee safety, especially in facilities requiring proper lighting, ventilation, or climate control. Customer confidence erodes when service interruptions occur, potentially driving clients toward competitors with more stable operations.

Regulatory compliance becomes problematic as businesses struggle to maintain required documentation and safety protocols during outages. The cumulative effect of unreliable electricity extends beyond temporary inconvenience, threatening long-term viability and market position.

Assessing Current Electrical Infrastructure and Identifying Weak Points

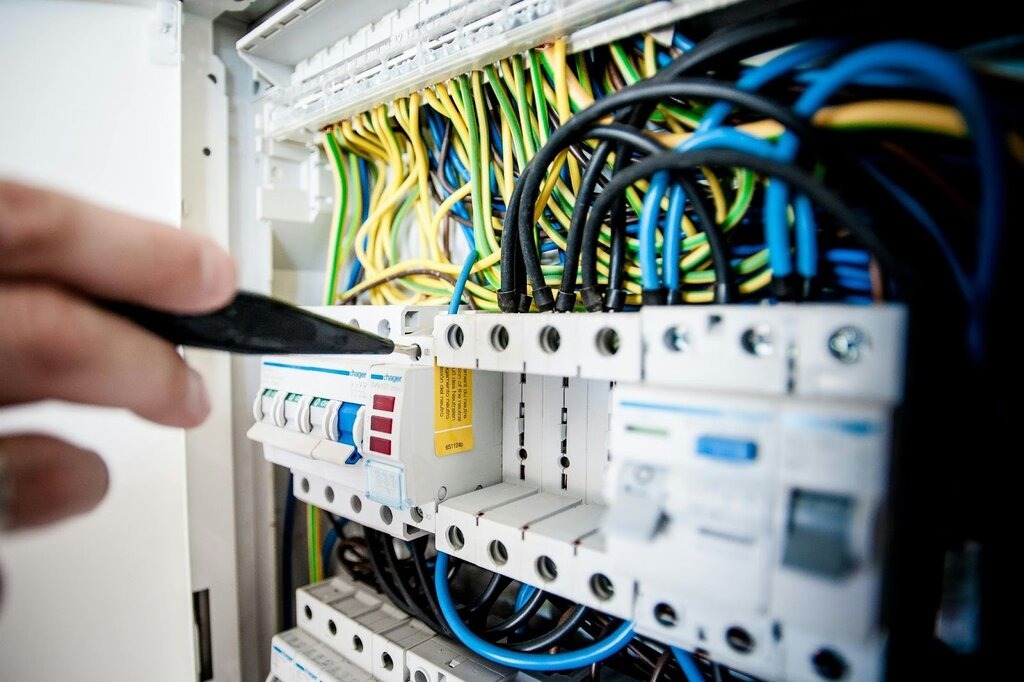

Before implementing improvements, organizations must conduct thorough evaluations of existing electrical systems to pinpoint vulnerabilities that threaten operational continuity. Professional audits should examine distribution panels, circuit breakers, wiring age, and load capacity against current operational demands. Thermal imaging identifies overheating components before failures occur, while power quality monitoring reveals voltage fluctuations, harmonics, and transient issues affecting sensitive equipment.

Critical assessment areas include backup power systems, uninterruptible power supplies, and automatic transfer switches. Organizations should document single points of failure where one component’s breakdown halts operations. Maintenance records expose patterns of recurring problems indicating systemic weaknesses. Load analysis determines whether circuits operate near maximum capacity, leaving insufficient margin for expansion. This detailed infrastructure review establishes baseline conditions and priorities for targeted remediation efforts.

Upgrading Critical Components With Durable Medium Voltage Power Distribution Cables

After identifying infrastructure vulnerabilities, organizations can prioritize replacement of aging power distribution cables that present the highest risk to system reliability. Medium voltage cables rated between 1kV and 35kV form the backbone of electrical distribution systems, making their durability vital for uninterrupted operations. Many facilities now standardize medium voltage power distribution cables across new projects to ensure consistent performance and long-term system resilience.

Modern cable designs incorporating cross-linked polyethylene (XLPE) insulation offer superior thermal performance and resistance to environmental stress compared to legacy paper-insulated cables. These upgrades considerably reduce failure rates and extend service life to 30-40 years under proper conditions.

Critical replacement factors include cable age, insulation degradation, moisture ingress, and thermal cycling exposure. Organizations should establish systematic replacement schedules based on condition assessments rather than reactive maintenance approaches. Investing in quality medium voltage cables with appropriate ratings for anticipated loads minimizes downtime risks and guarantees long-term operational continuity.

Implementing Preventive Maintenance and Routine Electrical System Monitoring

Establishing a thorough preventive maintenance program allows organizations to detect electrical system anomalies before they escalate into costly failures. Regular thermal imaging scans identify hot spots in connections, breakers, and transformers that signal deteriorating components. Scheduled insulation resistance testing reveals degradation in cables and equipment before breakdowns occur. Power quality monitoring detects voltage fluctuations, harmonics, and transient events that compromise sensitive equipment and reduce operational efficiency.

Documentation of inspection findings, test results, and maintenance activities creates valuable historical data for trend analysis and predictive maintenance strategies. Implementing automated monitoring systems provides real-time alerts when parameters exceed safe thresholds, enabling immediate corrective action. Training maintenance personnel on proper testing procedures and safety protocols guarantees consistent execution of preventive measures, maximizing electrical system reliability and minimizing unplanned downtime.

Strengthening Backup Power Systems to Protect Operations During Outages

Even with extensive preventive maintenance programs, external factors and unforeseen circumstances can interrupt utility power supply. Organizations must implement robust backup power systems to maintain critical operations during outages. Uninterruptible power supplies (UPS) provide immediate battery-based protection for sensitive equipment, bridging gaps until generators activate. Diesel or natural gas generators offer extended runtime for essential loads, requiring proper sizing calculations based on actual power demands and startup requirements.

Regular testing schedules guarantee backup systems function correctly when needed. Monthly generator exercises under load verify mechanical integrity and fuel quality. Battery health monitoring detects degradation before failures occur. Transfer switch maintenance assures seamless shifts between power sources. Documentation of system capacities, fuel reserves, and runtime limitations enables informed decisions during emergencies. Automated monitoring systems alert personnel to equipment malfunctions or fuel shortages, preventing unexpected backup system failures.

Training Staff and Establishing Clear Electrical Safety Protocols

Thorough electrical safety training forms the foundation of accident prevention and regulatory compliance in any facility handling power distribution systems. Organizations must implement extensive programs covering lockout/tagout procedures, arc flash hazards, proper PPE usage, and emergency response protocols. Staff should receive role-specific instruction based on their interaction level with electrical equipment, from basic awareness for general employees to advanced training for maintenance personnel.

Written safety protocols must document standard operating procedures, equipment-specific guidelines, and incident reporting requirements. Regular refresher courses promote knowledge retention while addressing evolving standards and new equipment installations. Conducting periodic safety audits and drills reinforces proper practices and identifies gaps in protocol adherence. Documentation of all training sessions creates accountability and demonstrates compliance during regulatory inspections, ultimately reducing workplace injuries and equipment damage.