Your automated production line just stopped unexpectedly. The culprit? A faulty proximity sensor that your supplier shipped three months ago. Now you’re facing costly downtime, missed orders, and frustrated customers waiting for their products.

This scenario plays out daily in Singapore’s manufacturing facilities. The right proximity sensor supplier can mean the difference between smooth operations and expensive disruptions. Let’s explore how to choose a supplier that keeps your automation running flawlessly.

The Critical Role of Proximity Sensors in Automation

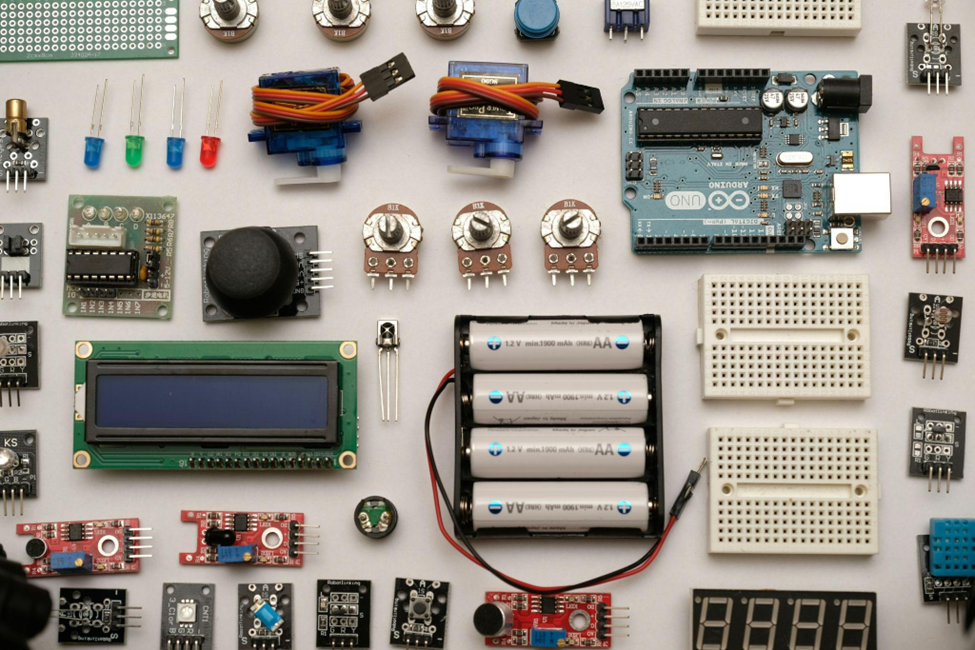

Proximity sensors are the eyes and ears of modern automated systems. They detect objects without physical contact, triggering programmed responses in your control systems. In Singapore’s high-tech manufacturing sector, these sensors power everything from semiconductor production to food packaging lines.

Without reliable sensors, your entire automation strategy collapses. A single sensor failure can cascade through your production line, causing delays worth thousands of dollars per hour. The quality of your sensors directly impacts your bottom line.

Most facility managers underestimate how much their operations depend on these small but critical components. One automotive parts manufacturer in Jurong lost $80,000 in a single day due to sensor failures. Their bargain supplier couldn’t provide immediate replacements.

Understanding Your Sensor Requirements

Before you find a proximity sensor supplier, you need to understand exactly what your system requires. Different applications demand different sensor types, sensing ranges, and environmental specifications. Getting this wrong means buying sensors that won’t work or won’t last.

Start by documenting your current setup. What materials are you detecting? What are the typical sensing distances? What environmental conditions exist (temperature, humidity, dust, chemicals)?

Industrial environments in Singapore present unique challenges. High humidity, temperature fluctuations in non-air-conditioned warehouses, and corrosive substances in chemical plants all affect sensor performance. Your supplier must understand these local conditions.

Types of Proximity Sensors Explained

Inductive proximity sensors detect metallic objects and are perfect for metal fabrication and automotive applications. They’re rugged, reliable, and widely used in Singapore’s manufacturing sector. However, they won’t detect non-metallic materials like plastics or wood.

Capacitive sensors detect both metallic and non-metallic objects, including liquids and powders. Food processing plants and pharmaceutical facilities rely heavily on these sensors. They’re more sensitive to environmental conditions than inductive sensors.

Photoelectric sensors use light beams to detect objects at longer distances, making them ideal for conveyor systems and packaging lines. Ultrasonic sensors use sound waves and work well in dusty or steamy environments. Each type has specific strengths that match particular applications.

The Hidden Costs of Poor Supplier Choices

Cheap sensors seem attractive until they fail during peak production. A food manufacturer in Woodlands learned this lesson when their budget sensors lasted only four months instead of the expected two years. Replacement costs, downtime, and rush shipping fees tripled their actual sensor expenses.

Poor technical support compounds the problem. When sensors malfunction at 2 AM during a critical production run, you need immediate expert assistance. Budget suppliers rarely offer 24/7 technical support or rapid replacement services.

Inconsistent quality creates unpredictable failures. One batch works perfectly while the next fails within weeks. This inconsistency makes preventive maintenance impossible and forces reactive repairs at the worst possible times.

What Makes a Quality Proximity Sensor Supplier

Quality suppliers stock sensors from reputable manufacturers with proven track records. Brands like Omron, Sick, Balluff, and Pepperl+Fuchs dominate because they invest heavily in research, testing, and quality control. These manufacturers back their products with comprehensive warranties.

Local inventory matters enormously in Singapore’s fast-paced industrial environment. Suppliers with Singapore-based warehouses can deliver replacement sensors within hours, not days. This rapid response minimizes costly production downtime.

Technical expertise separates great suppliers from mediocre ones. Can their engineers help you select the right sensor for your specific application? Do they understand your industry’s unique challenges? Will they visit your facility to assess requirements?

Evaluating Supplier Certifications and Standards

ISO certifications indicate a supplier’s commitment to quality management systems. Look for ISO 9001 certification at a minimum. Suppliers serving critical industries often hold additional certifications like ISO 14001 for environmental management.

Product certifications matter too. Sensors used in explosive environments need ATEX or IECEx certification. Food processing applications require sensors meeting FDA standards. Medical device manufacturers need sensors compliant with stringent healthcare regulations.

Singapore’s regulatory environment demands compliance with local standards. Your supplier should understand SS (Singapore Standards) requirements and help ensure your automation systems meet all regulatory obligations. Non-compliance can result in costly retrofits or legal issues.

The Importance of Technical Support

Pre-sales technical support helps you select the correct sensors before purchasing. Quality suppliers employ experienced engineers who ask detailed questions about your application. They’ll recommend alternatives if your initial choice isn’t optimal.

Post-sales support becomes critical when problems arise. Can you reach a knowledgeable technician quickly? Do they offer phone, email, and on-site support? Some suppliers provide remote troubleshooting using video calls, speeding up problem resolution.

Training programs help your maintenance team understand sensor installation, calibration, and troubleshooting. Well-trained staff can often resolve minor issues without calling for external support. This capability significantly reduces downtime and maintenance costs.

Understanding Program Control Integration

Modern manufacturing relies on sophisticated 程序控制 systems that coordinate multiple sensors and actuators. Your proximity sensors must integrate seamlessly with PLCs, SCADA systems, and other automation components. Compatibility issues can cripple even the most carefully planned upgrades.

Different sensors use various output signals: NPN, PNP, analog voltage, or current. Your supplier must help you match sensor outputs to your control system inputs. Mismatched signals lead to unreliable operation or complete system failure.

Communication protocols add another layer of complexity. Industrial networks like Profibus, EtherNet/IP, and Modbus require sensors with appropriate communication interfaces. Your supplier should stock sensors compatible with your existing network infrastructure.

Inventory Management and Lead Times

Singapore’s limited storage space makes just-in-time inventory crucial. However, relying entirely on immediate availability is risky when production depends on specific sensors. Finding the right balance requires a supplier who understands your usage patterns.

Lead times vary dramatically between suppliers. Some stock hundreds of sensor varieties locally, while others order from overseas warehouses. A three-day lead time versus a three-week lead time can determine whether your production continues or stops.

Emergency availability separates exceptional suppliers from average ones. When a critical sensor fails on Saturday night, can your supplier provide a replacement? Some maintain after-hours emergency stocks specifically for this purpose.

Price vs. Quality: Finding the Balance

The cheapest sensor rarely delivers the best value. Factor in lifespan, reliability, warranty coverage, and support when comparing prices. A sensor costing twice as much but lasting four times longer saves money long-term.

Total cost of ownership includes purchase price, installation costs, maintenance expenses, and downtime costs from failures. Quality sensors from reputable suppliers typically deliver 30-50% lower total cost of ownership despite higher initial prices.

Volume discounts matter for large-scale operations. Suppliers willing to negotiate long-term supply agreements can significantly reduce per-unit costs. However, never sacrifice quality or service for marginal price savings.

Supplier Relationships and Long-Term Partnerships

View your sensor supplier as a strategic partner, not just a vendor. Strong relationships lead to preferential treatment during supply shortages, customized solutions for unique challenges, and insider knowledge about new technologies.

Regular supplier reviews ensure ongoing performance meets your expectations. Track metrics like delivery times, product quality, technical support responsiveness, and problem resolution speed. Address issues promptly before they impact operations.

Long-term partnerships often unlock additional benefits. Suppliers may offer exclusive access to new products, priority allocation during shortages, or customized training programs. These advantages accumulate over time.

Evaluating Local vs. International Suppliers

Singapore-based suppliers offer proximity advantages: faster delivery, easier communication, and better understanding of local regulations. They can visit your facility quickly when problems arise. However, their product range might be more limited than international suppliers.

International suppliers often offer broader product selections and potentially better pricing. However, shipping delays, communication time zones, and currency fluctuations create complexity. Returns and warranty claims become more complicated.

Hybrid approaches work well for many operations. Source common sensors locally for immediate availability while ordering specialized sensors internationally with longer planning horizons. This strategy balances speed, cost, and availability.

Digital Tools and Online Ordering

Modern suppliers provide online catalogs with detailed specifications, datasheets, and CAD models. These resources speed up sensor selection and installation planning. Look for suppliers whose websites offer comprehensive technical information.

Online ordering systems should integrate with your procurement software. Automated reordering based on inventory levels reduces administrative burden. Order tracking and shipping notifications help you plan maintenance activities.

Mobile apps from leading suppliers enable field technicians to identify and order replacement sensors directly from the production floor. This capability eliminates delays caused by administrative processes and reduces critical downtime.

Environmental and Sustainability Considerations

Singapore’s strong environmental focus means choosing suppliers committed to sustainability. Look for sensors manufactured using eco-friendly processes with minimal environmental impact. Energy-efficient sensors reduce operational costs while supporting green initiatives.

Supplier recycling programs for failed sensors demonstrate environmental responsibility. Some suppliers offer sensor refurbishment services, extending product lifecycles while reducing waste. These programs align with Singapore’s circular economy goals.

RoHS compliance ensures sensors don’t contain hazardous substances like lead or mercury. This compliance protects workers, simplifies disposal, and meets increasingly strict environmental regulations.

Testing and Validation Before Full Deployment

Always test new sensors in actual operating conditions before large-scale deployment. Request sample units from prospective suppliers for pilot testing. This validation identifies potential issues before they become expensive problems.

Document test results thoroughly. Measure detection accuracy, response times, and reliability under various conditions. Compare performance against manufacturer specifications and your operational requirements.

Involve your maintenance team in testing. Their hands-on experience often reveals practical issues that specifications don’t address. Their buy-in also ensures smooth implementation when you scale up deployment.

Making Your Final Decision

Create a weighted scoring system for supplier evaluation. Factors might include product quality (30%), technical support (25%), local availability (20%), pricing (15%), and long-term partnership potential (10%). Adjust weights based on your priorities.

Don’t rush the decision process. A hasty choice often leads to long-term regrets and expensive corrections. Take time to verify supplier claims through reference checks with existing customers.

Start with smaller orders to test supplier performance before committing to large-scale supply agreements. This gradual approach minimizes risk while building confidence in your supplier choice.

Implementing Your Upgrade Plan

Develop a phased replacement schedule rather than attempting wholesale system upgrades. This approach reduces risk, spreads costs, and allows learning from early installations. Begin with non-critical systems to gain experience.

Document everything: sensor locations, configurations, wiring diagrams, and troubleshooting procedures. This documentation proves invaluable when problems arise or when training new maintenance staff.

Establish clear success metrics for your upgrade: reduced downtime, lower maintenance costs, improved production consistency, or enhanced safety. Track these metrics to validate your supplier choice and guide future decisions.

Conclusion

Choosing the right proximity sensor supplier impacts your automation system’s reliability, operational costs, and production efficiency. Quality suppliers provide more than just products; they offer technical expertise, rapid support, and long-term partnership value.

Don’t let price alone drive your decision. Consider the total cost of ownership, technical support quality, local availability, and supplier reliability. The wrong supplier costs far more than any initial savings.

Invest time in a thorough supplier evaluation. Your production facility’s success depends on the reliability of every component, especially the sensors that make automation possible. Choose wisely, and your program control systems will deliver years of dependable performance.