The automotive industry is a driving force of technological innovation, constantly seeking ways to enhance the performance, efficiency, and safety of vehicles. Laser cutting technology has emerged as a transformative tool in this pursuit, revolutionizing the manufacturing process with its unparalleled precision and versatility. As industries recognize the potential of laser cutting in achieving manufacturing excellence, the automotive sector is poised to witness increased adoption, further solidifying its role as a cornerstone in the quest for precision and innovation in vehicle production.

Fundamentals of Laser Cutting

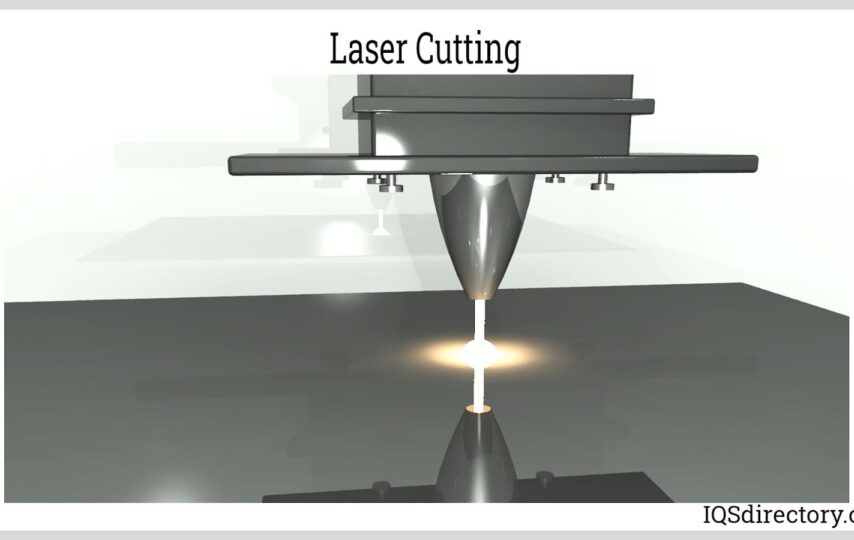

At the heart of laser cutting lies a fundamental principle: the focused energy of a laser beam can precisely cut through various materials. This process involves directing a high-intensity laser beam onto the material, causing it to melt, vaporize, or ablate, depending on the material’s properties and the laser’s parameters.

Types of Lasers in Automotive Manufacturing

In the realm of automotive manufacturing, laser cutting machine have become indispensable tools, with each type tailored to address specific production needs. Carbon dioxide (CO2) lasers, renowned for their versatility, find extensive use in cutting an array of materials ranging from plastics to metals and composites. Their adaptability contributes significantly to the efficiency of the manufacturing process, making laser cutting machines integral to achieving precision and versatility in automotive production.

On the other hand, fiber lasers are making notable strides in the automotive industry, garnering attention for their exceptional efficiency and high beam quality. This type of laser technology is increasingly preferred due to its precision and effectiveness in various applications within the automotive sector. As manufacturers continually seek advancements to enhance productivity and precision, the role of lasers, especially CO2 and fiber lasers, continues to evolve, shaping the landscape of automotive manufacturing.

Key Components of a Laser Cutting System

The key components of a laser cutting system work in tandem to achieve unparalleled precision in automotive manufacturing. These components, including the laser source, optics, and control system, orchestrate a seamless process, ensuring accurate and efficient fabrication of intricate automotive components.

A laser cutting system comprises several essential components that work in unison to deliver precise and controlled cutting. These include:

- Laser source: The heart of the system, generating the high-energy laser beam.

- Laser delivery system: Guides the laser beam to the cutting area.

- Cutting head: Houses the laser optics and focuses the beam onto the material.

- Computer numerical control (CNC) system: Controls the movement of the cutting head and laser parameters.

Specific Uses of Laser Cutting in Automotive Manufacturing

Laser cut in automotive manufacturing serves as a transformative force, shaping excellence in various applications. From precision-cut body panels to intricate interior components, laser technology plays a pivotal role in crafting high-quality and intricately designed automotive parts, enhancing overall manufacturing precision and efficiency.

Laser cutting’s versatility is evident in its diverse applications across various automotive components. From intricately shaping body panels to precision-cutting engine parts, this technology plays a pivotal role in enhancing efficiency, precision, and customization in the manufacturing of automotive elements.

Body and Chassis Components:

Body and chassis components represent a critical domain for laser cutting applications in automotive manufacturing. The precision afforded by laser technology ensures accurate fabrication of body panels and structural elements, contributing to the overall integrity, safety, and aesthetic appeal of the vehicle.

- Precision Cutting for Body Panels: Laser cutting technology excels in delivering immaculate, precision cuts for automotive body panels. This not only minimizes the necessity for additional finishing processes but also significantly elevates the overall quality of the panels, meeting the stringent standards of the automotive industry.

- Fabrication of Structural Elements: In the realm of automotive manufacturing, laser cutting emerges as a pivotal tool for fabricating essential structural components like frames and pillars. Its capability to ensure dimensional accuracy and structural integrity proves instrumental in creating robust and reliable elements crucial for the safety and performance of vehicles.

Interior Components

Laser cutting plays a pivotal role in shaping intricate interior components for automobiles. From precision-cut dashboard elements to seat and upholstery production, this technology ensures high-quality, customized, and aesthetically pleasing interiors in automotive manufacturing.

- Dashboard and console fabrication: Laser cutting facilitates the precise fabrication of dashboards and consoles, enabling intricate designs and enhanced aesthetics.

- Seat and upholstery production: Laser cutting is employed in seat and upholstery production, creating precise patterns and ensuring a perfect fit for interior components.

Engine and Drivetrain Components

Laser cutting revolutionizes the fabrication of engine and drivetrain components in automotive manufacturing. Ensuring precision in cutting engine parts and enhancing the production of transmission and exhaust system elements, this technology contributes to improved performance and efficiency in the automotive industry.

- Cutting precision for engine parts: Laser cutting ensures precision in cutting engine components, such as valves, gaskets, and seals, contributing to engine performance and reliability.

- Transmission and exhaust system applications: Laser cutting finds applications in the fabrication of transmission components and exhaust system components, ensuring precise fit and durability.

Benefits of Laser Cutting in Automotive Production

Laser cutting in automotive production offers a myriad of benefits. It ensures precise cuts for body panels, reducing the need for secondary finishing, and enhances overall quality. Additionally, laser cutting plays a crucial role in fabricating structural elements, guaranteeing dimensional accuracy and bolstering structural integrity.

- Enhanced precision and accuracy: Laser cutting delivers unmatched precision and accuracy, reducing errors and inconsistencies in component fabrication.

- Reduction in material waste: Laser cutting’s narrow heat-affected zone minimizes material waste, promoting resource efficiency and cost savings.

- Increased production efficiency: Laser cutting’s high speed and automation capabilities significantly enhance production efficiency, reducing production time and costs.

- Flexibility in design and customization: Laser cutting’s versatility enables the production of intricate designs and customized components, catering to evolving automotive trends.

Challenges and Considerations

Incorporating laser cutting in automotive manufacturing presents challenges and considerations that require careful navigation. Factors such as initial setup costs, ongoing maintenance requirements, and safety considerations underscore the need for a balanced approach when embracing this cutting-edge technology in the production process.

While laser cutting offers immense advantages, it also presents challenges to consider:

- Initial setup costs: Laser cutting equipment demands a substantial upfront investment, necessitating thorough financial scrutiny and strategic planning to ensure a sound and sustainable implementation.

- Maintenance requirements: To guarantee peak performance and durability, laser cutting systems mandate routine maintenance, emphasizing the importance of a proactive and systematic upkeep schedule.

- Safety considerations: Laser cutting operations necessitate rigorous safety protocols and comprehensive training. Prioritizing operator well-being, these measures aim to mitigate potential hazards and create a secure working environment.

Case Studies

Automotive manufacturers worldwide are embracing laser cutting to achieve manufacturing excellence, resulting in enhanced precision, reduced material waste, increased production efficiency, and flexibility in design and customization.

Ford Motor Company

Ford revolutionized F-150 production by employing laser cutting to craft lightweight, robust body panels. This strategic move resulted in a remarkable 700-pound weight reduction, enhancing the F-150’s fuel efficiency by an impressive 20%, showcasing the transformative impact of laser technology in automotive engineering.

BMW Group

In pursuit of precision, the BMW Group integrated laser cutting into the fabrication of intricate engine components for their luxury vehicles. This technological advancement ensured meticulous adherence to tolerances, elevating engine performance and reliability to new heights, underscoring the pivotal role of laser cutting in precision engineering.

Toyota Motor Corporation

Toyota harnessed the versatility of laser cutting to realize intricate interior designs for their Lexus luxury vehicles. This innovative approach surpassed the limitations of traditional manufacturing methods, enabling Toyota to craft unique and elaborate interior aesthetics that defined the luxurious experience offered by Lexus vehicles.

These are just a few examples of how automotive manufacturers are using laser cutting to improve their products and processes. As laser cutting technology continues to evolve, it is likely to play an even greater role in the automotive industry in the years to come.

Future Trends in Laser Cutting for Automotive Components

Rapid advancements in laser cutting technology for automotive components signify a transformative era. The integration of cutting-edge innovations promises heightened precision, increased efficiency, and expanded material capabilities, paving the way for a future where automotive manufacturing embraces unprecedented levels of sophistication and performance.

Advancements in laser technology

Advancements in laser technology are rapidly transforming manufacturing. Innovations include improved cutting precision, increased power efficiency, and enhanced adaptability to diverse materials, driving the evolution of industries such as automotive manufacturing towards greater efficiency and precision.

- Higher power lasers will enable the cutting of thicker materials, such as high-strength steels and aluminum alloys.

- Improved beam quality will enable the cutting of more complex geometries, such as those found in lightweight components and intricate designs.

Integration with automation and artificial intelligence

The integration of laser cutting with automation and artificial intelligence is reshaping industries. Automated systems enhance precision, while AI algorithms optimize cutting parameters in real-time, revolutionizing efficiency and customization in manufacturing processes, including automotive production.

- Laser cutting systems will become more integrated with automation and artificial intelligence, enabling real-time process monitoring and optimization. This will help to improve the quality and consistency of laser-cut parts.

- Laser cutting systems will be able to learn from data collected during the manufacturing process and use this data to improve their performance.

Potential for increased adoption in the industry

The potential for increased adoption of laser cutting in the industry is significant. As the technology continues to prove its efficacy in enhancing precision, efficiency, and customization, more sectors, including automotive manufacturing, are poised to embrace and integrate laser cutting solutions into their production processes.

- Laser Cutting Technology Maturity: As laser cutting technology advances and becomes more refined, automotive manufacturers are increasingly likely to integrate it into their production processes. The maturation brings forth enhanced precision, speed, and efficiency, promising transformative benefits for the industry.

- Cost Reduction and Affordability: The decreasing costs associated with laser cutting technology make it a highly attractive option for automotive manufacturers. This affordability opens the door for widespread adoption, enabling companies to leverage the versatile benefits of laser cutting without imposing prohibitive financial constraints.

Conclusion

Laser cutting stands as a transformative force within the automotive industry, leaving an indelible mark on manufacturing processes. Its influence is profound, marked by heightened precision, diminished material waste, heightened production efficiency, and newfound avenues for design and customization. The adoption of laser cutting technology has empowered automotive manufacturers, enabling them to craft superior cars and trucks. The trajectory suggests that the automotive industry will witness further advancements and refinements, cementing laser cutting as a cornerstone technology shaping the future landscape of vehicle production.