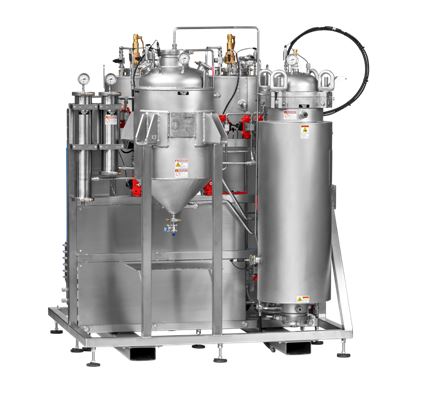

Calibrating and putting in a Butane Hash Oil (BHO) extraction system according to manufacturer specifications is foundational for achieving the most beneficial effects. Accurate calibration of temperature, stress settings, and retaining suitable butane-to-material ratios are pivotal elements that appreciably impact the efficiency and exceptional extraction approaches. Adherence to endorsed parameters ensures not best consistency and safety in operations but also maximizes yield and enhances the nice of extracted concentrates.

Accurate Temperature and Pressure Settings

Precise temperature control is critical at some point in ensuring the BHO extraction equipment efficiency. Maintaining the best temperature range ensures the upkeep of terpenes and cannabinoids even as warding off thermal degradation. Each stress or sort of fabric may also have the most reliable temperature for extraction, and particular manipulation within this variety is critical to attaining favored profiles.

Similarly, controlling strain settings in extraction structures is important. Pressure affects the solubility and extraction performance of cannabinoids and terpenes from the plant material. Manufacturer-advocated pressure parameters need to be strictly followed to optimize extraction efficiency without compromising the protection of the manner.

Appropriate Butane-to-Material Ratios

The ratio of butane to the material being extracted plays a pivotal role in the performance and best of the extraction procedure. The best ratio might also vary depending on the unique material being processed, and adhering to these ratios is crucial. Using the precise quantity of butane ensures green extraction without excess solvent, which can in any other case negatively affect the final product’s purity.

Consistency and Safety

Adherence to manufacturer specs guarantees consistency and repeatability in extraction approaches. Consistent calibration and setup parameters cause predictable results, bearing in mind the dependable manufacturing of splendid concentrates batch after batch. Moreover, preserving these requirements guarantees the protection of the extraction technique, reducing the threat of accidents or equipment malfunction.

Maximizing Yield and Quality

Proper calibration and setup at once impact the yield and nice of extracted concentrates. When the extraction system operates inside premier parameters, it maximizes the yield of preferred compounds even while minimizing the extraction of undesirable materials. This meticulous manipulation outcome concentrates on better potency, higher flavor profiles, and stepped forward overall exceptional.

Compliance and Regulatory Standards

Following producer specs and recommended settings is not only much operational efficiency and product quality; it also guarantees compliance with regulatory standards. In industries wherein cannabis extraction is regulated, strict adherence to installed parameters is essential for assembly felony requirements and keeping product integrity.

Quality Control Checks

Implement a strong fine manipulation system to regularly verify the accuracy of calibration and setup. Periodic tests and validations of temperature, strain, and butane-to-material ratios in opposition to predefined requirements or benchmarks ensure ongoing accuracy and reliability in the extraction manner.

Optimization through Experimentation

While adhering to manufacturer specs is important, exploring mild versions inside safe limits may optimize extraction performance. Systematically experimenting with minor modifications in temperature, stress, or solvent ratios underneath controlled situations can result in improved yields or improved extract profiles without compromising safety or niceness.

Continuous Monitoring and Analysis

Utilize superior tracking structures and records evaluation equipment to tune and analyze extraction parameters in actual time. Continuous monitoring permits fast modifications, ensuring that the gadget operates inside the most useful stages. Analyzing records traits through the years can also display styles that assist in refining extraction protocols for higher efficiency and satisfaction.

Regular Equipment Upgrades and Maintenance

Invest in ordinary system upgrades and improvements to make sure compatibility with evolving enterprise standards and technological upgrades. Upgraded additives or more modern models would possibly offer more advantageous features that improve efficiency, precision, and safety. Additionally, everyday upkeep schedules, which include scheduled component replacements and machine assessments, are essential to uphold optimal functionality and save you unexpected breakdowns.

Environmental Considerations and Energy Efficiency

Consider the environmental effect and energy intake of extraction tactics. Implement electricity-efficient practices and equipment wherein possible, reducing the carbon footprint of operations. An efficient system no longer best reduces prices but additionally aligns with sustainability desires, selling a greener method to extraction techniques.

Best Practices for Calibration and Setup

- Read Manufacturer Guidelines: Thoroughly apprehend the producer’s instructions, guidelines, and specs for the precise extraction equipment getting used.

- Precision Instruments: Utilize extraordinary and correct gadgets for measuring and controlling temperature, stress, and solvent-to-cloth ratios.

- Regular Maintenance: Conduct habitual device tests, maintenance, and calibrations to make sure constant overall performance and accuracy.

- Record Keeping: Maintain exact information of calibration procedures, settings, and any adjustments made for future reference and exceptional control functions.

- Training and Education: Ensure that personnel working the equipment are well-skilled and informed approximately the calibration system to hold consistency and safety.

Final Words

In the end, the meticulous calibration and setup of the BHO extraction device or cannabis extraction equipment in keeping with manufacturer specs are essential pillars for achieving efficient and great extraction processes. Adherence to those parameters guarantees consistency, safety, regulatory compliance, and the manufacturing of superior concentrates, ultimately contributing to the achievement and reputation of extraction operations.