The oil water separation industry is undergoing rapid innovation. As environmental regulations tighten and corporations adopt more sustainable practices, demand has increased for advanced solutions that remove oils and solvents from water more efficiently. Companies specializing in oil water separators and related wastewater treatment technologies have responded with continuous development of enhanced separation techniques, automated smart systems, and environmentally-conscious designs.

Staying current with the latest trends and understanding forthcoming innovations allows businesses to plan ahead to capitalize on improvements while maintaining regulatory compliance. Adopting cutting-edge, tested technologies further reduces operating costs through boosted energy efficiency. This article highlights the trajectory of advances in oil water separation to inform strategic investment.

The field of oil water separation remains dynamic. As new techniques and materials emerge from R&D laboratories, existing separation products and protocols steadily improve. Specifying future-forward solutions aligned with forthcoming regulations ensures industrial facilities avoid costly reworks down the line. Partnering early with established innovative manufacturers for oil water separator technologies also allows customization for specific use case needs rather than one-size-fits-all offerings.

There exist clear competitive advantages for businesses proactively adopting advanced oil water separation systems as commercialization accelerates. Keeping abreast of new testing methodologies and enhanced treatment options allows corporations to plan demonstration pilots with the latest equipment. Early testing produces data to build business cases backing company-wide adoption rollouts. The undertaking delivers a quick ROI through boosted oil recovery and energy savings.

Current State of Oil Water Separation Technology

Common separation solutions traditionally utilize gravity via oil-water separators to leverage density differentials. Oils float to the top for capture while particulates sink to the bottom sludge layers. Limitations arise when dealing with finely dispersed oil droplets or emulsified oils requiring chemical addition to encourage coalescence. Sample technologies include parallel inclined plate separators, horizontal flow tubular separators, and dissolved air flotation systems.

While time-tested, conventional separation systems need help to capture oils with specific gravities nearing water through inefficiency and needing large footprints. Fouling issues also increase maintenance. Open equipment allows VOC atmospheric emissions amid strenuous site approvals. Finally, the inability to sense oil content complicates optimizing chemical addition and determining discharge readiness without extensive sampling. Simply put, aging tech hampers oil removal.

Emerging Trends and Innovations

Enhanced Efficiency and Effectiveness

Micro-surface membrane contactors leverage engineered media, enabling over 140 square meters of surface area per module to interact with oily wastewater. This concentrates separated oil for easier removal without chemicals that would degrade membranes. The technology achieves discharge levels of less than five ppm oil while occupying minimal space.

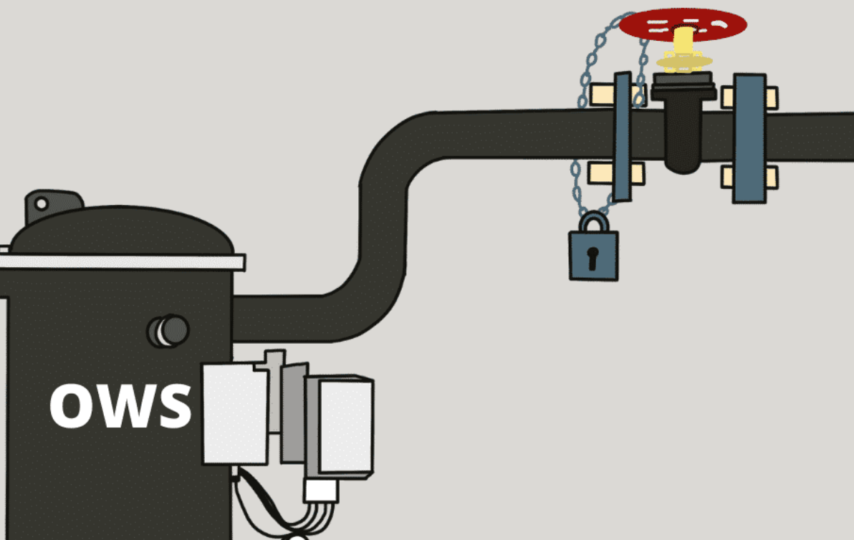

Automation and Smart Monitoring

New electronic sensing accurately determines separated oil and grease contents post-treatment for automated valve control. Program logic only permits discharge once stringent concentration and content volume thresholds are met. These innovative separators interface with data monitoring software tracking metrics like oil spilled, water usage and energy consumption using dashboards. Preventive alerts also activate given irregular readings, preventing environmental incidents.

Modular and Scalable Designs

Pre-built modular oil water separation systems enable affordable scaling. Aftermarket additions of mixer tanks, extra media contactors, and sensors integrate seamlessly via plug-and-play simplicity without re-engineering. Flexible configurations suit tight spaces through compact stacks supporting multi-stage treatment trains.

Resource Recovery and Sustainability

Some emerging separators concentrate separated oils in holding tanks for reclamation, targeting biodiesel production representing high-value waste-to-product conversion. Earlier designs wasted captured oils by blending them back with sludge for costly disposal. This cradle-to-cradle approach boosts profitability by recovering valuable petrochemicals on-site.

Integration with Green Initiatives

New separation installations often link with existing rainwater harvesting infrastructure to treat collected water for boiler feed or other plant reuse. Combining these systems curtails potable water demands through circular water integration, which supports corporate water reduction goals and LEED certification.

Regulatory Compliance and Standards

Look for modern oil water separation technologies tested against the strictest certification protocols like UL-2215, validating extra environmental protections and leak prevention. As regulations impose lower permissible oil content in discharged wastewater, only the latest enhancements meet evolving compliance needs into the foreseeable future without significant retrofits.

Future Outlook and Predictions

Building upon current momentum, oil water separation technology will likely see expanded automation through AI optimization, maximizing self-adjusting chemical dosing, component longevity, and energy efficiency using operating data. Continued modularization also allows tailored pairing to upstream and downstream water treatment trains. Lastly, sensors will grow more sensitive to trace hydrocarbons while stabilizing readings despite fouling and abrasion.

The advent of smart oil water separation unlocks game-changing reductions in operating expenses and environmental incidents through predictive insights coupled with responsive controls. As innovations emerge from labs to commercial availability, plants willing to pilot test and provide user feedback position themselves to capture outsized competitive advantages as early adopters once proven. Companies staying current position themselves to lead their industries on sustainability and operational excellence by being first to integrate step-change advancements.

Summary

In closing, the oil water separation technology landscape continues advancing through cutting-edge efficiency and automation enhancements. Emerging sensing improvements, increasingly compact modular designs, and resource recovery techniques offer tantalizing productivity, compliance, and ROI benefits while minimizing land use. Corporations proactively partner with separation specialists on tailored solutions to level themselves up for transformative gains over industry peers anchored to outdated legacy installations. Prioritizing pilot tests of pioneering innovations today pioneers operational breakthroughs tomorrow.

The foregoing analysis highlights the compelling near-future capabilities of emerging oil water separation systems. The impressive breadth of pilot-ready upgrades makes clear that continued R&D investment reaps rich dividends as measured by informed corporations willing to fund controlled technology trials and provide feedback to separation innovators. Channeling resources into promising technologies promises to uplift systemwide performance while cementing corporate sustainability bona fides. The possibilities make strategic commitments to advancing oil water separation compelling.