Product design engineering is a rapidly evolving field that has become an integral part of the modern manufacturing process. Product design engineering is a complex process that requires a deep understanding of the needs of the customer, the environment, and the materials used to create the product. Professional product design engineering services involve the use of sophisticated and innovative techniques to create products that are both aesthetically pleasing and functionally efficient.

In this article, we will explore how product design engineering can be used to create powerful and successful products. We will examine the tools used in the process, the importance of understanding customer needs, and the potential benefits of product design engineering.

Introduction

Product design engineering is the process of creating products that combine form and function. It involves the use of advanced tools and techniques to create products that are both aesthetically pleasing and functionally efficient. The goal of product design engineering is to create products that meet the needs of the customer while also being cost-effective and easy to use.

The process of product design engineering typically involves the following steps:

1. Identifying customer needs: The first step of product design engineering is to identify the needs of the customer. This involves understanding the customer’s requirements and researching the market to determine what types of products are most likely to meet those needs.

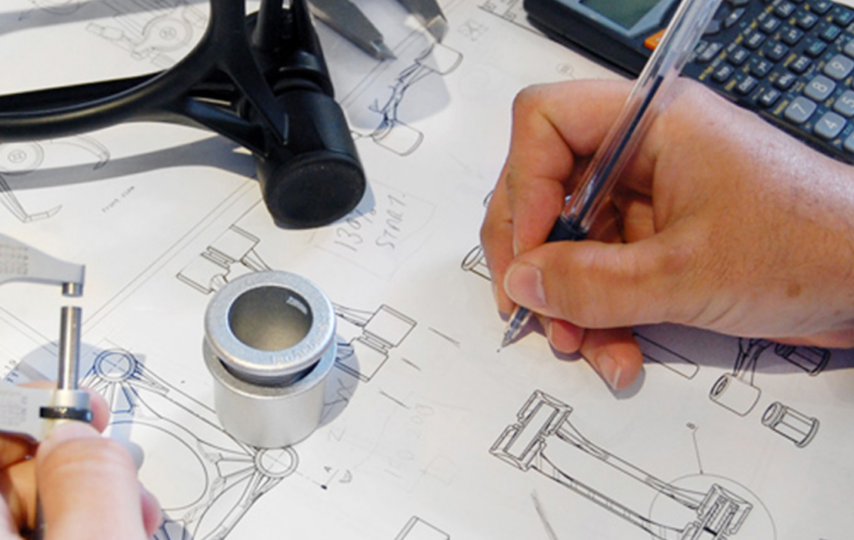

2. Brainstorming and concept development: Once the customer’s needs have been identified, the next step is to brainstorm ideas and develop concepts for potential products. This can be done through brainstorming sessions, concept drawings, and other creative methods.

3. Designing the product: Once the concept has been developed, the next step is to design the product. This involves creating detailed drawings and specifications for the product using CAD software.

4. Prototype creation: After the design has been completed, a prototype of the product can be created. This prototype can then be tested to ensure that it meets the customer’s needs and is cost-effective and efficient.

5. Testing and refinement: After the prototype has been created, it must be tested to ensure that it meets the customer’s needs and is cost-effective and efficient. Testing can involve real-world testing, such as field testing, or simulated testing, such as computer simulations.

6. Manufacturing: The final step of product design engineering is to create the product for sale. This involves the use of advanced manufacturing techniques and materials to create the product.

Benefits of Product Design Engineering

Product design engineering can provide a number of benefits for both the manufacturer and the customer. Some of the potential benefits include:

1. Increased efficiency: Product design engineering can help to increase the efficiency of the product development process. By using advanced tools and techniques, product designers can create products that are both aesthetically pleasing and functionally efficient.

2. Improved customer satisfaction: Product design engineering can help to create products that meet the needs of the customer. This can lead to increased customer satisfaction and loyalty.

3. Cost savings: Product design engineering can help to reduce the cost of creating products. By using advanced tools and techniques, product designers can create products that are both aesthetically pleasing and cost-effective.

4. Improved safety: Product design engineering can help to improve the safety of the product. By using advanced tools and techniques, product designers can create products that are both aesthetically pleasing and safe to use.

Conclusion

Product design engineering is a rapidly evolving field that has become an integral part of the modern manufacturing process. It involves the use of sophisticated and innovative techniques to create products that are both aesthetically pleasing and functionally efficient. Product design engineering can provide a number of benefits, such as increased efficiency, improved customer satisfaction, cost savings, and improved safety. Product designers must understand the needs of the customer, the environment, and the materials used to create the product in order to create powerful and successful products.