We often see different types of machines and devices and use them daily, but have we ever thought of how they manufactured? We might come across with the assembling method, i.e. just assembling different machinery components and then putting them together with tools. But before creating any machine, there are numerous processes that take place for each element. Sheet metal fabrication is one of the primary techniques that take place before building any machinery. It is a fantastic process of transforming metal into sheets and making them useful in the basic structure of all kinds of machinery types. Metal fabrication can be referred to as a broad term to cut, mould, polish, and shape them for different purposes.Visit Evans Manufacturing Co for Metal Fabrication Seattle.

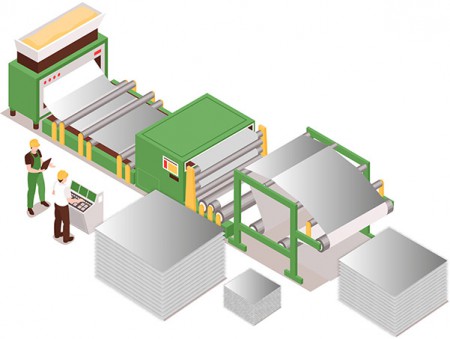

Many different steps took place in manufacturing a metal in any kind of desirable form. The specialized sheet metal fabrication machines perform every effort from selecting an appropriate metal material to the end product. These machines are specially designed for casting, cutting, folding, drawing, stamping and welding. Every step is performed in a series in order to get a good end material. In the processing of any metal, there are specified methods that take place according to the type of material used in it.

Some basic types of sheet metal fabrications for all the variety of metals are as follows:

- Casting: Casting is the process when a metal is heated to its melting point and then poured into a mould so that it is changed into a desirable shape for the other operations of the metal. There is a variety in casting a metal like; Die-Casting method, Semi-permanent method, etc. Casting is done in a suitable environment and based on properties of a metal.

- Cutting: It is one of the prevalent forms of fabrication that can be witnessed easily in any manufacturing shop and a vital step to perform. Plasma arc cutting, Rotary die cutting and Flatbed die cutting are the most common methods used in the process of cutting.

- Drawing: The desired amount of tensile force is used to pull into and through the machine to reduce the sheet’s thickness known as drawing. It uses the property of the metal called malleability. This process helps to get metal into an acceptable consistency for its different further usage.

- Folding and Forging: Folding is a method of bending a metal sheet with the help of a brake press that creates creases in the metal by pinching it. On the other hand, forging, uses a hammer or hard strikes on the metal to transform into a shape that we desire. These processes are usually performed when the metal is heated.

- Machining: It refers to the process of removing unwanted materials from the metal. A raw metal always comes with many impurities and an amalgamation of different metals. It is important to extract unwanted residues and make it more smooth and ductile.

- Stamping: Stamping is mainly used to form shapes, letters, or images in a metal panel or sheet. There are two types of stamping, i.e. Mechanical and Hydraulic. This process is used to create wide ranges of products like metal coining. It has been considered as the most effective method in the smaller form of metals.

- Welding: Welding is the last but not the least spet in the fabrication of metal. We all are very much familiar with this method and it is commonly used by all the manufacturers from small to big. This step plays a prominent role in combining two different metal sheets. There are different welding types like Stick welding, Metal Inert Gas Welding, Tungsten Inert Gas Welding and Flux Cored Arc Welding.

Sheet metal fabrication machines are no less than wonder machinery to us. We even see all the above-mentioned processes as individuals. But performing all the processes within one machine is difficult to even imagine. Machines have not only cut down the long processes but also have been a great hand in every sector. Every basic necessity of ours can be easily fulfilled by a device. Sheet metal fabrication machines provide the basic supplements to the machine manufacturer and decrease the time, and money spends otherwise on each step. Good fabrication machinery helps to manufacture rate, production quality, and cost-effectiveness of a given project. If you’re interested in purchasing metal sheet stock, click here.