Environmental monitoring and control systems are essential in various domains, ensuring optimal conditions for human comfort, industrial processes, and scientific endeavors.

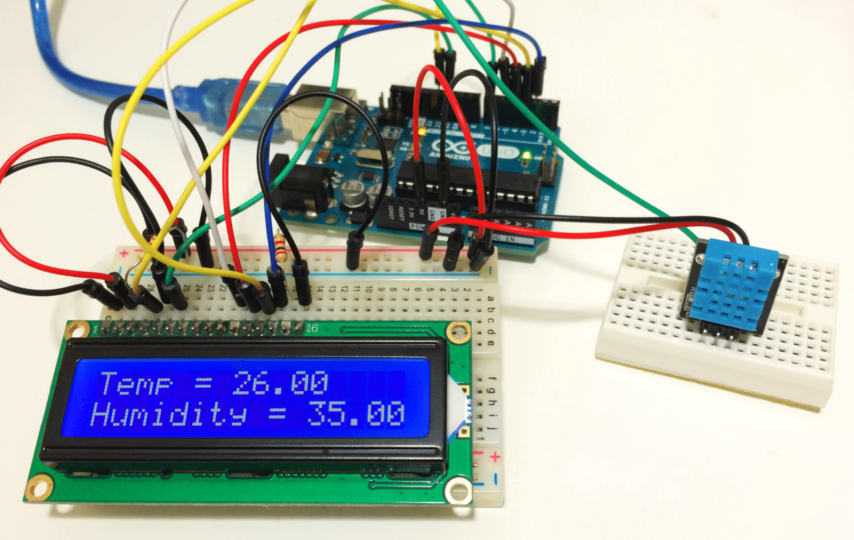

Temperature sensors and humidity sensors are integral components of environmental monitoring and control systems. While both play pivotal roles in assessing and managing environmental conditions, they serve distinct purposes and operate on diverse principles.

Purpose and Measurement Parameter of Temperature and Humidity Sensors

Temperature sensors measure heat, which is crucial in science and industry. Humidity sensors, however, focus on moisture levels, which are vital for comfort, agriculture, weather forecasting, and preservation. Both sensor types play pivotal roles in diverse fields. Delve more deeply into the purpose and measurement parameters of temperature sensors and humidity sensors:

- Temperature Sensors

Purpose:

Temperature sensors are instrumental in measuring temperature, a fundamental physical parameter with extensive applications across various fields. Their core purpose is to evaluate and quantify the thermal conditions of environments, objects, or systems. Temperature measurements offer vital insights into heat transfer, energy transfer, and the physical state of matter. This foundational role makes temperature sensors indispensable in numerous scientific and technological areas.

Applications:

Temperature sensors find widespread utility in diverse applications, owing to the fundamental significance of temperature in the natural world. Key applications include:

- Climate Control in Buildings

Temperature sensors regulate heating and cooling systems in HVAC (Heating, Ventilation, and Air Conditioning) systems to maintain indoor comfort.

- Automotive Industry

These sensors monitor engine temperature, ensuring vehicles’ safe and efficient operation.

- Food Safety

Temperature sensors are critical in cooking appliances, preventing foodborne illnesses by monitoring and controlling cooking temperatures.

- Industrial Processes

In industrial automation, temperature sensors control and monitor temperatures in processes such as chemical reactions, material production, and metallurgy.

- Weather Monitoring

Meteorologists use temperature sensors to monitor and forecast weather conditions, playing a vital role in climate understanding and predicting weather events.

- Medical Applications

In healthcare, temperature sensors are integrated into devices like thermometers and incubators, helping to monitor and regulate patient body temperature.

- Environmental Monitoring

Temperature sensors track changes in natural environments, aiding in climate change studies and ecological research in ecosystems like oceans, lakes, and forests.

- Humidity Sensors

Purpose:

Humidity sensors are specialized instruments engineered to measure humidity or moisture levels in the air. Humidity quantifies the quantity of water vapor in the atmosphere and holds critical importance across various domains. The primary objective of humidity sensors is to assess and quantify atmospheric moisture content.

Applications:

Humidity sensors serve vital roles in applications where precise control of humidity levels is imperative. They are widely utilized in diverse fields for various purposes, including:

- Indoor Climate Control

In residential and commercial buildings, humidity sensors are integrated into HVAC systems to regulate indoor humidity levels, ensuring human comfort, health, and energy efficiency.

- Agriculture

In agriculture, humidity sensors are employed in greenhouses and controlled environment agriculture (CEA) setups to optimize crop growth, prevent diseases, and enhance yields.

- Meteorology

Weather stations and meteorological instruments rely on humidity sensors to measure and monitor atmospheric moisture levels, which is crucial for weather forecasting and climate studies.

- Pharmaceutical and Food Industry

Humidity control is pivotal in pharmaceutical and food manufacturing processes, ensuring product quality, stability, and shelf life.

- Electronics Manufacturing

Humidity sensors are used in electronics manufacturing to prevent moisture-related damage to sensitive electronic components.

- Storage and Preservation

These sensors monitor and control humidity levels in storage facilities, museums, and archives, preventing the deterioration of artifacts, documents, and stored goods.

- Energy Efficiency

In data centers and industrial facilities, humidity sensors optimize energy efficiency and enhance equipment performance by controlling environmental conditions.

Types Of Temperature Sensors And Humidity Sensors

The choice in selecting between temperature sensors and humidity sensors depends on the specific application requirements, including the desired temperature or humidity range, accuracy needs, response time, and budget constraints. Each sensor type has strengths and weaknesses, making them suitable for different scenarios. Refer to the tables below to understand their differences.

| Temperature Sensor Types | ||

| Principle | Advantages | |

| Thermocouples | Operate based on the Seebeck effect, where two dissimilar metals generate a voltage proportional to the temperature difference between junctions. | Wide temperature range, rugged, suitable for high-temperature environments, rapid response. |

| Thermistors | Temperature-sensitive resistors with predictable resistance-temperature relationship. | High accuracy within a limited range, fast response, cost-effective. |

| Infrared Sensors | Detect infrared radiation from objects, intensity correlates with temperature. | Non-contact measurement, suitable for remote or hazardous environments, rapid response. |

| Humidity Sensor Types | ||

| Principle | Advantages | |

| Capacitive Humidity Sensors | Rely on capacitance changes as moisture is absorbed or desorbed by a hygroscopic material. | High accuracy, rapid response, low hysteresis. |

| Resistive Humidity Sensors | Vary electrical resistance with moisture absorption or desorption. | Suitable for various humidity levels, cost-effective, integratable. |

| Gravimetric Humidity Sensors | Measure humidity by monitoring weight change of a moisture-absorbing material. | High accuracy, robust, unaffected by contaminants. |

| Advantages and Limitations | ||

| Temperature Sensors | ||

| Advantages | Limitations | |

| Thermocouples | Wide range, high-temperature suitability. | Moderate accuracy, susceptibility to interference. |

| Thermistors | High accuracy, fast response. | Limited range, non-linearity. |

| Infrared Sensors | Non-contact, rapid response. | Limited range, cost for precision. |

| Humidity Sensors | ||

| Advantages | Limitations | |

| Capacitive Humidity Sensors | High accuracy, rapid response. | Susceptibility to contamination, periodic calibration. |

| Resistive Humidity Sensors | Suitable for various levels, cost-effective. | Lower accuracy, slower response. |

| Gravimetric Humidity Sensors | High accuracy, robust. | Slow response, limited real-time monitoring, relatively expensive. |

Factors Affecting Accuracy of Temperature and Humidity Sensors

Temperature sensors and humidity sensors are vital in many industries, but their accuracy is crucial for reliable data. Below is the discussion that explores factors affecting their precision, including sensor type, environment, calibration, placement, quality, and interference, to enhance sensor performance and data reliability.

- Sensor Type

- Temperature Sensors

The type of temperature sensor used can significantly impact accuracy. For instance, thermocouples, while versatile, may have lower inherent accuracy compared to more precise options like thermistors or precision RTDs (Resistance Temperature Detectors).

- Humidity Sensors

Similarly, the choice of humidity sensor type matters. Capacitive humidity sensors generally offer higher accuracy than resistive sensors due to their better sensitivity and linearity.

- Environmental Conditions

Both temperature and humidity sensors are sensitive to their operating environment. Fluctuations in temperature, humidity, and pressure can affect the accuracy of these sensors. Sensors must be protected from environmental factors that can introduce errors, such as direct sunlight, drafts, or moisture ingress.

- Calibration Drift

Over time, sensors may deviate from their initial calibration. This drift can occur due to various factors, including aging, contamination, or exposure to extreme conditions. Regular recalibration is essential to maintain accuracy and correct for this drift.

- Sensor Placement

The placement of sensors plays a crucial role in their accuracy. Correct placement can lead to accurate readings. For example, if a temperature sensor is placed too close to a heat source or in an area with poor airflow in HVAC systems, it may not accurately represent the overall room temperature.

- Sensor Quality

The quality and manufacturing precision of the sensor itself can vary significantly. Higher-quality sensors typically offer better accuracy and stability. Investing in sensors from reputable manufacturers can help ensure reliable measurements.

- Interference

Interference from electromagnetic fields, nearby electronic devices, or other sensors can introduce errors in temperature and humidity measurements. Shielding and proper sensor placement can help mitigate interference.

Calibration of Temperature and Humidity Sensors

Calibration is a crucial process to ensure temperature and humidity sensors provide accurate and reliable measurements. Here are the key steps involved in sensor calibration:

- Reference Standard

Begin by using a reference standard or a calibrated instrument with known accuracy as a reference. To ensure accuracy, this reference standard should be traceable to a recognized national or international standard.

- Comparison

Place the sensor to be calibrated alongside the reference standard in an environment with stable conditions. Ensure that both sensors are exposed to the same temperature and humidity levels during calibration.

- Data Collection

Record readings from both the sensor under calibration and the reference standard simultaneously. This involves varying the conditions if needed to cover the sensor’s entire measurement range.

- Analysis

Compare the readings from the calibrated sensor to those from the reference standard. Calculate the deviation or error at various points within the sensor’s measurement range.

- Adjustment

If the sensor’s readings deviate from the reference standard, make necessary adjustments to the sensor. This adjustment may involve changing sensor settings, modifying calibration coefficients, or making physical corrections.

- Repeat and Fine-Tune

Repeatedly compare the sensor’s readings with the reference standard, making additional adjustments as needed. Fine-tune the calibration until the sensor’s measurements are within the desired level of accuracy.

Challenges in Sensor Calibration

- Traceability

Ensuring that the reference standard used for calibration is traceable to a recognized national or international standard can be challenging. Traceability is essential to establish the accuracy of the calibration process and to maintain confidence in measurement results.

- Environmental Variations

Maintaining stable and controlled environmental conditions during calibration can be difficult, especially in field applications where conditions may be less predictable.

- Sensor Drift

Sensors can exhibit drift over time, necessitating periodic recalibration to maintain accuracy. Predicting and compensating for sensor drift is an ongoing challenge.

- Interference

Minimizing interference from external factors, such as electromagnetic fields, can be challenging, especially in industrial settings where multiple sensors and devices are in close proximity.

- Cost and Resources

Calibrating sensors often requires specialized equipment and trained personnel, which can be costly and resource-intensive. Managing these resources effectively is crucial to the calibration process’s success and efficiency.

Explore Reliable Solutions at MISUMI Thailand for Your Temperature Sensor

In the realm of environmental monitoring and control, temperature and humidity sensors are indispensable tools for ensuring optimal conditions in various applications. Although different in their purposes and operating principles, these sensors collectively contribute to human comfort, industrial processes, scientific research, and more.

If you want to purchase a temperature sensor to meet your specific needs, you may visit MISUMI Thailand and explore our selection of temperature sensors and other industrial components. You’ll find the suitable sensor for your application with our extensive range of products and a reliable reputation. Also, MISUMI offers specialized solutions if you need heat shrink tubing for insulating electrical cables or protecting conductive metal parts in various devices. Visit us at https://th.misumi-ec.com and be our partner in sourcing top-quality industrial components, ensuring the safety and efficiency of your projects.