The steel construction industry is a rapidly changing and evolving sector of manufacturing which requires solutions that can keep up with current trends. One such solution is the tube laser cutter, which is revolutionizing the way steel constructions are built and assembled.

What Is A Tube Laser Cutter?

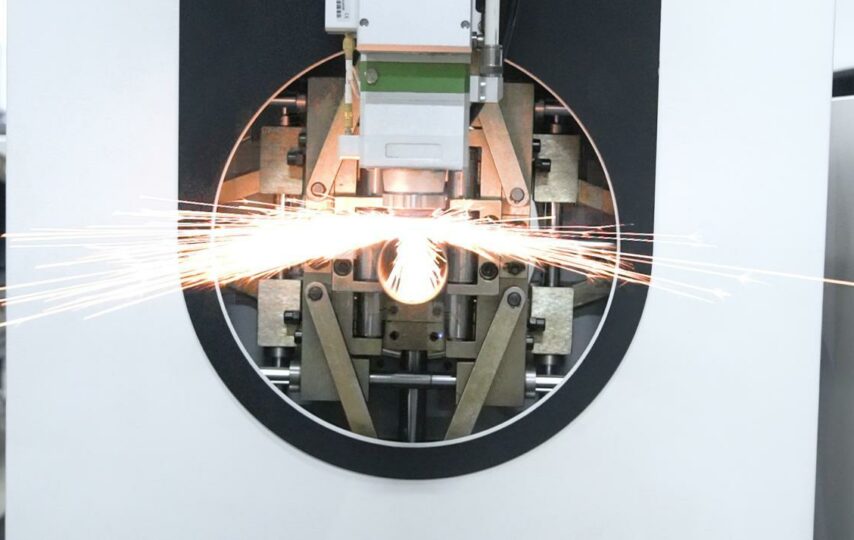

A tube laser cutter is a specialized machine that utilizes a high-intensity laser beam to cut and form tubing, pipes and tubes from various metals. A large number of small and large diameters of tubes can be cut with great precision and accuracy. The main advantages of this cutting technique is its high speed, accuracy, portability and flexibility.

What Are The Benefits Of A Tube Laser Cutter?

There are many benefits of using a tube laser cutter in the steel construction industry:

-

- No heat treatment or post-processing required – air cooling technology helps to avoid distortion

-

- Highly accurate and repeatable cuts – advanced cutting technology ensures precision and accuracy and ensures that repeatable cuts can be made each time

-

- Lower operating costs – compared to alternative cutting methods, tube laser cutting can be up to 85% more cost-effective

-

- Better weld quality – since no heat is generated during the cutting process, there is less risk of warping and distortion which leads to a better weld quality

-

- Increased safety – automated cutting processes reduce operator fatigue, therefore increasing safety in the workplace

Conclusion

The tube laser cutter is a versatile and cost-effective solution for the steel construction industry. With its high accuracy and repeatable cuts, it is rapidly gaining popularity. Improved safety and weld quality are additional benefits that must not be overlooked.

What is the accuracy and cutting capacity of a tube laser cutter in the steel construction industry?

The accuracy and cutting capacity of a tube laser cutter in the steel construction industry vary depending on the type of laser used and the material thickness being cut. Generally speaking, laser tube cutters are capable of cutting 6mm or 0.23 inch thick materials with a tolerance of +/- 0.005 of an inch. The cut-edge surface may be +/- 0.020 of an inch and the edge radius can be as small as 0.005 of an inch.

What safety precautions should be taken when using a tube laser cutter for steel construction?

1. Wear safety gear such as safety glasses, hearing protection, and protective clothing when operating a tube laser cutter for steel construction.

2. Always wear gloves when handling material or machine parts to avoid burns.

3. Clear the work area of any combustible materials.

4. Make sure to inspect the equipment before each use and ensure it is properly grounded.

5. Install personal protective barriers around the laser cutter to protect from sparks, emissions and high temperatures.

6. Ensure there is adequate ventilation in the work area.

7. Ensure the safety interlocks are working and that all safety accessories are in place.

8. Make sure to remove any material scrap or debris away from the work area.

9. Never leave the work area unattended while the laser cutter is in use.

10. Shut off the machine and wait for all moving parts to completely stop before attempting to adjust or perform maintenance.

,

Laser cutting is a technology that has been around for more than 50 years and has a wide range of applications. Laser cutting can be used to cut a variety of materials including metals, plastics, and glass.

In recent years, laser cutting has become increasingly popular in the construction industry, as it offers a number of advantages over traditional cutting methods.

First and foremost, laser cutting is much faster than traditional methods such as sawing or grinding. Additionally, laser cutting produces a cleaner, more precise cut than other methods.

Another advantage of laser cutting is that it is a non-contact process, meaning there is no physical contact between the cutting tool and the material being cut. This means that there is less chance of damage to the material being cut, and the cutting process is less likely to cause any deformations.

Finally, laser cutting is a highly versatile technology that can be used to cut a variety of materials, including metals, plastics, and glass. This versatility makes laser cutting an ideal solution for a wide range of construction applications.

If you are looking for a fast, precise, and versatile cutting solution for your construction projects, then laser cutting is the ideal solution.