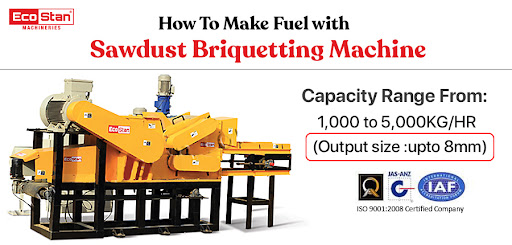

The significant use of the sawdust briquette machine is to produce high-calorie fuel briquettes from biomass. This machine discharges the briquettes evenly and cuts them to the appropriate length. For horticulture and Timberland, briquetting with a maximum moisture content of 8-12% is possible.

To further reduce moisture in wet biomass waste, strip dryers, rotary drum dryers, and hammer mill processors are used to dry it. By using ranger services and agricultural waste, such as wood scraps, you can use this Sawdust Making Machine to create briquettes that you can use for domestic heating, public heating, charcoal fuel processing facilities, and other applications.

The created sawdust briquette is another sustainable power with financially savvy execution. Many nations, including North America and Europe, have adopted it.

How to make fuel with a sawdust briquette machine Screw?

In some cases, sawdust briquettes require the use of several devices besides the sawdust briquette press, such as pond plants, dryers, and coolers. In any case, various customer circumstances call for different hardware. According to the real scenario and conditions, the best briquetting equipment can be altered.

- Sawdust Arrangement Interaction:

In the sawdust briquette machine Screw, the sawdust should have a moisture content between 12% and 15% and a size of less than 3mm. Adding a hammer plant and a dryer will reduce the time spent processing sawdust if it does not meet the requirements.

- Briquetting Cycle:

After turning on the power, put the prepared sawdust into the sawdust molding press and watch how it is shaped into sawdust. You can change the size of the resulting sawdust briquette by changing the size of the forming sleeve. You can always check the sawdust briquette machine price online whenever you are thinking of buying it.

- Sawdust Briquette Cooling and Pressing Interaction:

To assemble the sawdust briquettes into packs or boxes, as they are made at high temperatures, it is essential to cool them. If you make sawdust for your utilization, you can place them in a cooling place for self-temperature decline. To increase the effectiveness of sawdust briquette creation, you should prepare the cooling machine and pressing machine to improve the nature of the sawdust briquette.

- Briquette Carbonization Cycle:

For clients who need additional charcoal creation, we likewise offer the structured venture of making biomass charcoal briquettes.

- Working Standard of Screw Briquette Machine:

Because of the straightforward design and handling guidelines, the Sawdust Making Machine is not difficult to learn and work with. The several parts are combined to form a Sawdust screw briquette that includes a packing sleeve, a cone-like expulsion screw, an engine, and a gearbox. The entire briquetting process is a course of densification.

The sawdust enters the packing chamber under self-gravity when the engine begins to work. With the driving of the intention power, the cone-like expulsion screw drives the sawdust into the pack sleeve.The screw briquette squeezing machine pushes the framing material out after unrolling of tension.

Specialized Information of GCBC Series Sawdust Briquette Press:

Hot deal sawdust screw briquetting machine presented by screw briquetting apparatus producer or provider, Guide on the course of sawdust briquetting cycle and How to begin sawdust briquetting business with restricted cost in Tanzania, Egypt, Morocco, Ghana.

Benefits of sawdust Briquettes machine:

The central marks of the briquette machine choose their improvement view point. Albeit the biomass briquette hardware has been around for quite a while, specific individuals wouldn’t comprehend why we should involve sawdust briquette as a biomass fuel.

The sawdust briquette machine used Screw fuel made by the biomass briquette machine is another kind of biomass energy. It can supplant kindling, clean coal, fuel and diesel, condensed oil gas, and so forth. Furthermore, you can use it in day-to-day ovens, gas boilers, modern boilers, and biomass power plants.

- Complete control electric Tricking gadget of the briquette machine:

It can change the dampness of the wood material, work on the adequacy of the age, guarantee the dependability of the design, and the arrival of briquettes.

- Wear-safe Briquette Machine:

To further develop the sawdust briquettes machine to adjust to the age of control, the crucial part needs to get the contrary wear material with special treatment and meet the work solicitation of making unending fixing.

- Ready to adjust to various natural substances:

The briquette machine should follow the taking care of and making of various unrefined components, acclimate to the pressure, and managing of different natural substances with high age efficiency and continuous creation.

- The Effect of Natural substances on Sawdust Briquette Gear:

With the disasters in transportation, stockpiling, and different methods, the reasonable gauge will only meet the demands of biomass briquette fuel. Most natural substances, for instance, sawdust, are hard to pack and stay looking like wells; 20% of the bunches need to be squeezed again before baking.

Moreover, the briquette saves the expense of putting away the oven, and dampness is simpler to control. In this way, in the long haul, it would be a brilliant choice to utilize the briquette rather than the crude squeezed material.

- The motivation behind the sawdust briquettes delivered by the gear, Transforming Waste into Fortune:

You can use the briquettes machine’s after-effects in metallurgy, the components business, healing, normal protection, and in addition, support matrix, average warming, etc. They have broad applications and prevalence. Aside from wood fragments and squander, sawdust also contains corn cobs, natural product branches, natural product trees, and corn stalks.

Conclusion:

The possibility of briquetting is utilizing unusable materials because of an absence of thickness and packing them into a potent fuel of a pleasing shape that can be singed like wood or charcoal. The briquettes have preferable physical and burning qualities over the underlying waste.

If you are planning to buy a sawdust briquetting machine, you should consider the sawdust briquette machine price but always maintain the quality of the machine. Look for the top manufacturer of sawdust machines, as they always provide you with the highest quality sawdust machines.