Label and packaging printing is an essential aspect of modern business, as it plays a critical role in product identification, marketing, and branding. Direct-to-film printing is a new and innovative printing technology that is revolutionizing the way labels and packaging are produced. This printing process involves printing designs and images directly onto a film substrate, eliminating the need for traditional printing plates and reducing the cost and time required to produce labels and packaging.

Advantages of Direct-to-Film Printing:

- Increased Efficiency: Direct-to-film printing eliminates the need for printing plates, reducing the time required to produce labels and packaging. This not only speeds up the printing process but also increases the accuracy and consistency of the designs.

- Lower Cost: Direct-to-film printing eliminates the cost of producing printing plates, reducing the cost of producing labels and packaging. Additionally, it is a more efficient process, reducing the cost per label or packaging item.

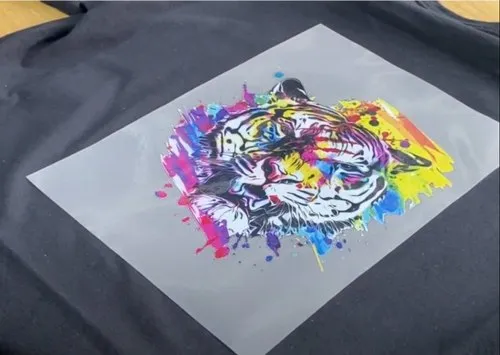

- Flexibility: Direct-to-film printing allows for greater flexibility in design, with the ability to print full-color designs and high-resolution images directly onto the film substrate. This opens up a world of creative possibilities for designers and marketers.

- Environmental Sustainability: Direct-to-film printing eliminates the need for the production of printing plates, reducing the waste and pollution associated with traditional printing methods. Additionally, the inks used in direct-to-film printing are water-based, which is a safer and more environmentally friendly alternative to traditional solvent-based inks.

- Quicker Turnaround Time: With direct-to-film printing, labels and packaging can be produced quickly and efficiently, allowing for faster turnaround times and quicker delivery of products.

Applications of Direct-to-Film Printing in Label and Packaging:

- Product Labels: Direct-to-film printing is ideal for producing product labels, as it allows for the creation of high-quality, full-color designs that are both eye-catching and functional.

- Food Packaging: Direct-to-film printing can be used to produce food packaging, such as snack packaging, beverage labels, and food-service packaging. This technology allows for the creation of high-quality, custom-designed packaging that is both functional and aesthetically pleasing.

- Cosmetic Packaging: Direct-to-film printing can be used to produce cosmetic packaging, such as lipstick tubes, compact packaging, and perfume boxes. This technology allows for the creation of high-quality, custom-designed packaging that is both functional and visually appealing.

- Short Run Orders: Direct-to-film printing is ideal for short run orders, where small quantities of labels or packaging items are needed. This is because the cost per item is lower with direct-to-film printing, making it a more cost-effective option for small orders.

Conclusion:

Direct-to-film printing is a game-changer in the label and packaging printing industry. Its increased efficiency, lower cost, and flexibility make it an ideal choice for the production of high-quality labels and packaging. From product labels to cosmetic packaging, direct-to-film printing has the ability to create unique and eye-catching designs that stand out from the crowd. With its many benefits, direct-to-film printing is poised to become a staple in the label and packaging printing industry for years to come.