Introduction

Butterfly valves are versatile players in fluid control systems. They find applications in various industries. They are popular because they are simple, efficient, and adaptable. People choose them to control fluid flow. This guide explores the many uses of butterfly valves. It explains their roles and the industries they serve.

Understanding Butterfly Valves

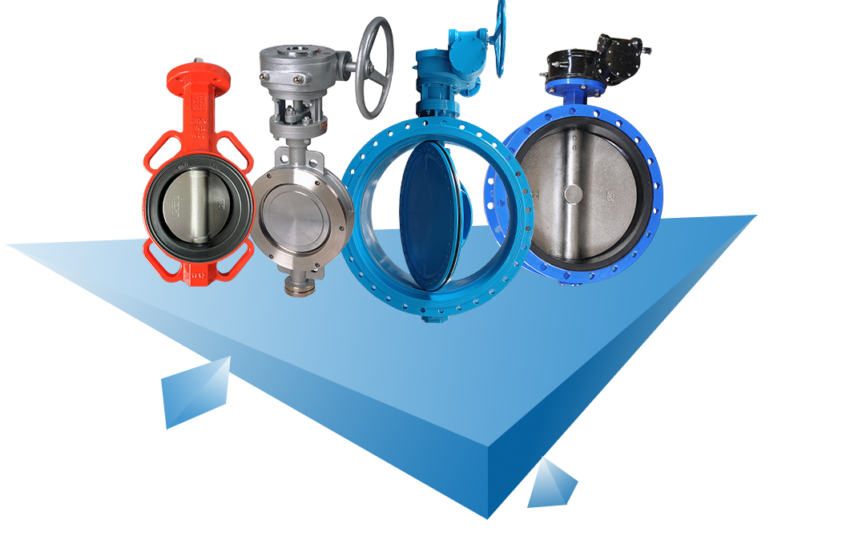

What Are Butterfly Valves?

Before we dive into their applications, let’s grasp the fundamentals. Butterfly valves are quarter-turn valves that employ a disk, resembling the wings of a butterfly, to control the flow of fluids. Their simple design enables fast and efficient use in various settings.

Applications of Butterfly Valves

Water Treatment Plants

Butterfly valves play a crucial role in water treatment plants where the regulation of water flow is paramount. Butterfly valves offer a reliable and cost-effective solution for water management. They control the flow of raw water, direct water through treatment processes, and manage the distribution of treated water.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on butterfly valves for controlling the flow of air and water. Valves adjust temperature and maintain ideal conditions in buildings. They are important for residential, commercial, and industrial use.

Oil and Gas Industry

Butterfly valves are used in the oil and gas sector. They regulate the flow of crude oil, natural gas, and petroleum products in pipelines. Their ability to handle large flow rates and their quick response make them indispensable in this demanding industry.

Chemical Processing Plants

Chemical processing plants often deal with corrosive and abrasive fluids. Butterfly valves use corrosion-resistant materials. They control chemical flow accurately and reliably in different processes.

Power Generation

Butterfly valves find applications in power plants for controlling the flow of cooling water, steam, and other fluids. Their efficiency and ease of operation make them valuable components in power generation systems.

Food and Beverage Industry

Butterfly valves are used in the food and beverage industry. They control the flow of liquids and gases in processing and packaging. Hygiene is important in this industry. Their smooth and clean design makes them suitable for applications where contamination is a concern.

Marine and Shipbuilding

Butterfly valves control water, fuel, and other fluids on ships. They are used in marine and shipbuilding applications, including offshore platforms. Their compact design and durability make them ideal for maritime environments.

Pulp and Paper Industry

In the pulp and paper industry, where various fluids are used in different stages of production, butterfly valves are utilized for controlling the flow of water, chemicals, and pulp slurries. Their versatility and cost-effectiveness contribute to their widespread use.

Mining Operations

In mining operations, butterfly valves are employed for controlling the flow of water, slurry, and chemicals. Their robust construction and ability to handle abrasive materials make them suitable for the demanding conditions of mining.

Agricultural Irrigation Systems

Butterfly valves are integral components in agricultural irrigation systems. They are used to regulate the flow of water to fields, ensuring efficient and controlled irrigation.

FAQ Section

How do butterfly valves operate?

Butterfly valves operate on a quarter-turn mechanism. When the handle or actuator is turned, the disc inside the valve rotates either parallel or perpendicular to the flow, regulating or blocking the fluid flow.

What are the advantages of using butterfly valves?

The advantages of butterfly valves include their simple and compact design, quick operation, cost-effectiveness, and suitability for a wide range of applications. They are also known for their low-pressure drop.

Are butterfly valves suitable for controlling high-pressure fluids?

Butterfly valves are generally suitable for moderate to low-pressure applications. For high-pressure systems, special high-performance butterfly valves with enhanced design features may be used.

Can butterfly valves be used for throttling applications?

While butterfly valves are primarily designed for on/off service, they can be used for throttling applications when equipped with the appropriate accessories and when precise control is not critical.

How do I select the right butterfly valve for my application?

Selecting the right butterfly valve involves considering factors such as the type of fluid, temperature, pressure, flow rate, and the specific requirements of the application. Consulting with valve experts or manufacturers can provide valuable guidance.

Automotive Manufacturing

Butterfly valves find application in automotive manufacturing processes, particularly in coolant systems. They help regulate the flow of coolant through the engine, ensuring optimal temperature control. The efficiency and quick response of butterfly valves contribute to the overall performance and reliability of automotive cooling systems.

Wastewater Treatment

In wastewater treatment plants, butterfly valves play a crucial role in managing the flow of wastewater through various treatment stages. These valves are utilized in channels, pipelines, and tanks to control the movement of sewage and facilitate the treatment processes. The resilience of butterfly valves to corrosive environments makes them well-suited for wastewater applications.

Conclusion

Butterfly valves, with their simplicity and adaptability, have become indispensable in various industries, contributing to the efficiency and reliability of fluid control systems. From water treatment plants to the oil and gas industry, these valves play a pivotal role in ensuring the seamless flow of fluids in diverse applications.